Warehouse lighting design: standards, layouts & luminaire selection

Warehouse lighting design: standards, layouts & luminaire selection

Introduction

In the fast-paced environment of the logistics industry, efficient warehouse lighting plays a vital role in improving operational efficiency, reducing energy costs and increasing worker productivity. Adequate lighting not only illuminates a vast space, but also significantly affects the overall functionality and safety of warehouse operations. However, warehouse lighting faces unique lighting challenges. The size of the space, ceiling height, and shelf layout all have an impact on the selection of lamps, the choice of lenses, and the layout of lamps. This guide explains the factors that need to be considered when implementing efficient lighting solutions in warehouse management, such as warehouse lighting standards and warehouse lighting design. Lighting design involves the dock area and rack area, and the choice of lamps and lighting distribution for these two areas is quite different. At the same time, dimming function, light efficiency (What’s light efficiency and how to improve it?), installation accessories also need to be considered when selecting lamps to achieve ideal lighting.

Warehouse lighting standard

There are many regional standards for warehouse lighting, such as ISO/CIE 8995, EN12464-1, and GB50034. For example, GB50034 requires 50lux, 100lux, 150lux, and 200lux for large parts warehouses, general parts warehouses, semi-finished product warehouses, and fine parts warehouses. In addition, the vertical illumination of the shelves should not be less than 50lx. ISO/CIE 8995 and EN12464-1 have similar requirements for warehouse lighting. The illumination requirement for store and stockrooms is 100lux, if they are continuously occupied then it requires 200lux. But it requires more light which is 300lux for dispatch packing handling areas. For the storage rack areas, there are obvious differences in the lighting requirements for unmanned and manned gangways, the former requires 20lux, while the latter requires 150lux. For storage rack face, the vertical illuminance requirement is greater than 200 lux(portable lighting may be used). The following are the requirements of EN12464-1 standard for illumination, uniformity and glare (What’s glare in lighting?) in different areas of the warehouse.

| General areas inside buildings – Store rooms, cold stores | |||||

| Type of area, task or activity | Em(lx) | UGR | Uo | Ra | Specific requirements |

| Store and stockrooms | 100 | 25 | 0,40 | 60 | 200 lx if continuously occupied. |

| Dispatch packing handling areas | 300 | 25 | 0,60 | 60 | |

| General areas inside buildings – Storage rack areas | |||||

| Type of area, task or activity | Em(lx) | UGR | Uo | Ra | Specific requirements |

| Gangways: unmanned | 20 | - | 0,40 | 40 | Illuminance at floor level. |

| Gangways: manned | 150 | 22 | 0,40 | 60 | Illuminance at floor level. |

| Control stations | 150 | 22 | 0,60 | 80 | |

| Storage rack face | 200 | - | 0,40 | 60 | Vertical illuminance, portable lighting may be used. |

Warehouse lighting design consideration

There is no essential difference between the storage space and the ceiling area of a general industrial plant, and the space is relatively simple. Warehouses are usually divided into docking areas and rack areas. Generally speaking, standard round beam angle high bay lights can be used for dock areas, but the rack area requires more efficient long and narrow beam angle lighting. Below we explain the points that need to be paid attention to in dock area and rack area lighting.

The lamps used for warehouse lighting should provide sufficient ground illumination. The lamps for dock area lighting should avoid skylights, air ducts, sprinklers, fans and other equipment installed on the ceiling. According to relevant lighting standards, such as EN12464 or IESNA, an average illumination of 200-300 lux is sufficient for the dock area. We generally use field arrangement to place lamps, and after calculation, we can get the desired results in lighting simulation. For this type of area lighting, the light distribution of lamps is mostly symmetrical, 60, 90, 120 degrees, which is decided by the lighting design (More ZGSM lighting designs).

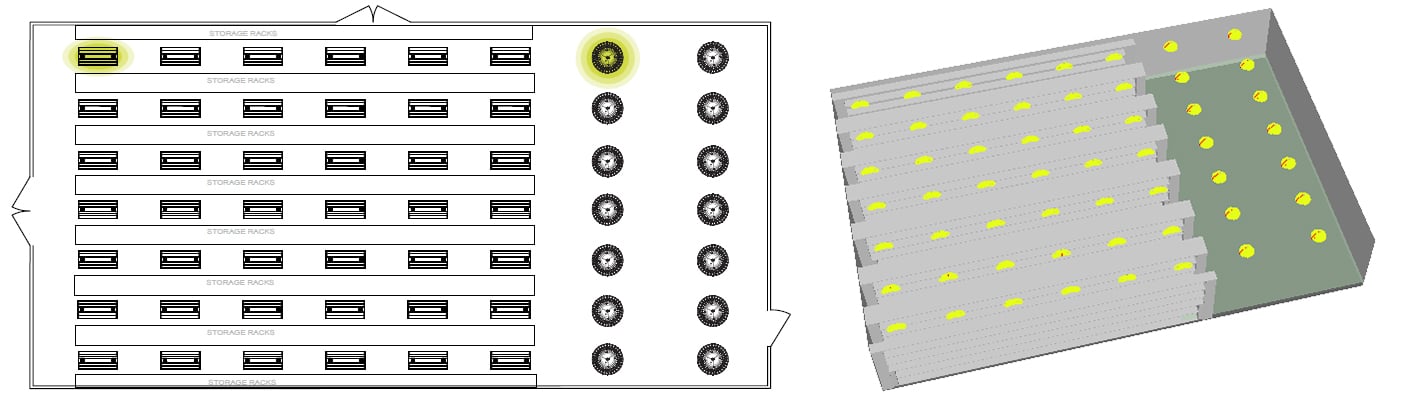

The lighting for the warehouse shelf area is relatively complex, because the aisles in the middle of the shelves are narrow. For example, for shelf-type storage, the aisle width of tall and large shelves that require stackers or forklifts to pick up and place stored items is generally 3~3.5m, while the aisle width of densely arranged shelves where manual storage items are placed is generally 1~1.5m. It is precisely because of these differences that we should reasonably select lamps and light distribution before warehouse lighting design according to parameters such as the height and spacing of the shelves to meet the lighting requirements of the shelf facade, especially the human eye observation area. For such areas, we give priority to lamps with asymmetric lighting or narrow lighting to meet the facade lighting requirements of the shelves, improve the recognition of goods and storage locations, and the accuracy of in-and-out storage operations.

How to choose the right LED light for warehouse lighting?

Installation method selection

There are different options for installing LED light for warehouse lighting, such as bracket mounted, surface-mounted, suspended mounted, pipe mounted, which are often determined by the structure of your warehouse. Bracket mounted can adjust the irradiation angle, which is suitable for shelf lighting or supplementary lighting in key areas; ceiling-mounted high-bay lights (surface mounted) are often suitable for warehouses with low ceilings; suspended mounted warehouse lights are often suitable for large warehouses with high ceilings; pipe mounted warehouse lights are relatively rare and are generally used to replace the original traditional lamps. Fine more about different installation ways.

High wattage and high light efficiency

As the height of the warehouse increases, the installation height of the lamps will also increase accordingly. We often need higher wattage LED lamps to illuminate the ground. For example, when the installation height is 6 meters, 8pcs 200W LED high bay lights can effectively illuminate an area of about 400 square meters (20*20 meters) (the average illumination can reach 500lux). But if you continue to increase the installation height, the lighting effect will become worse and worse because more light will be directed to the walls and ceiling. That’s why we need high wattage and narrow beam angle in this situation. It is also important to choose high-efficiency LED lamps. High-quality LED warehouse lights can reach 150 to 190 lm/W or even higher. This means that with the same number of LED lamps illuminating the target area, high-efficiency lamps can achieve the desired lighting effect with lower wattage. For the same 20*20 meter warehouse, if 140lm/W high bay lights are used, 8pcs 200W lamps can achieve the target illumination of 500lux. If 190lm/W is used, 8pcs 150W or 6pcs 200W high bay lights (ZGSM high luminous efficacy high bay light) will be enough.

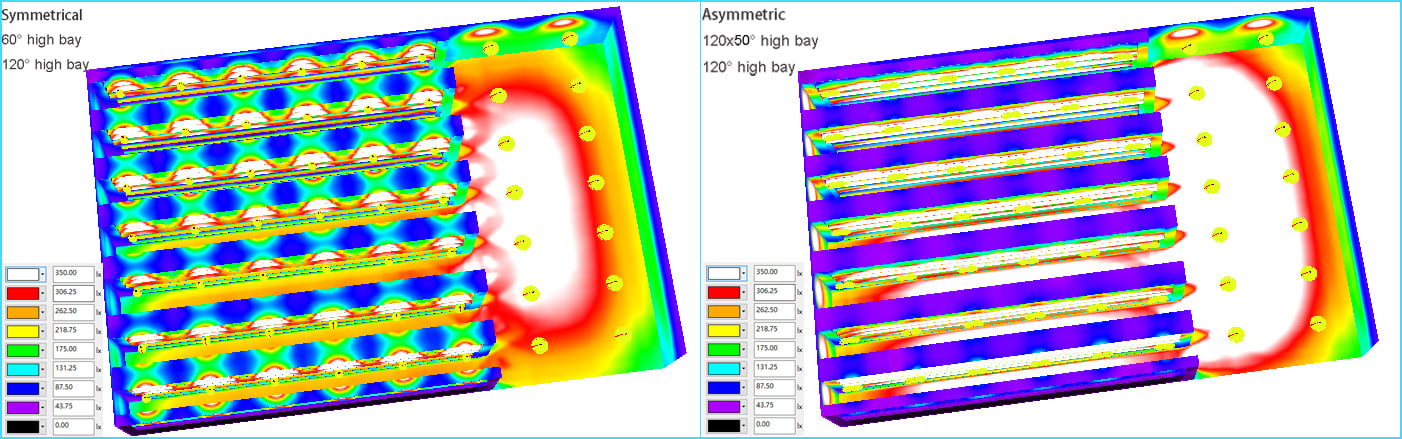

Light distribution selection

Through the analysis in the previous section, we know that the existence of shelves leads to narrow aisle width. In order to illuminate such a long and narrow aisle, we can imagine that symmetrical light distribution (What's symmetric and asymmetric light distribution?) is not suitable for this type of application scenario. On the contrary, asymmetrical lenses are very suitable for lighting such areas due to their differences in light distribution in the two directions of C0-180 and C90-270. The long light distribution of C0-180 is suitable for covering the entire aisle with light, while the short light distribution of C90-270 can concentrate the light and avoid irradiating the top of the shelves. We took a typical warehouse with shelves as an example of warehouse lighting design: the first solution completely adopted symmetrical light distribution, and the second solution combined asymmetric and symmetrical light distribution. After calculating by Dialux, we found that the lighting result of the former was far inferior to the latter. Not only was the illumination only about two thirds of the latter, but the uniformity was also poor, which could not meet the requirements of warehouse lighting for both. If we want to achieve higher illumination and uniformity, we either add lamps or choose a suitable light distribution. Obviously, the latter is a more reasonable and economical choice.

High temperature resistance, IP and IK rating

In warehouses with heating equipment, such as near boilers or in poorly ventilated areas, the temperature of the warehouse is often high. LED lights installed in such warehouses need to be able to withstand high temperatures. ZGSM HB13 series high bay lamps can operate in environments up to 65°C. This type of lamp is also suitable for high-temperature workshops, such as glass factories, smelters, power plants, etc. The HB13 series lamps use high operation temperature LED drivers, and the power supply is far away from the heatsink, which can greatly avoid the adverse effects of the heat of LEDs on the LED driver. These two features ensure that the lamps can operate at high temperatures. At the same time, this type of lamp should have a high protection level, allowing it to work in dusty and humid environments. These characteristics enable the lamps to withstand harsh working environments and avoid premature damage.

Other accessories such as emergency kit, anti-glare reflector

If the project needs to provide emergency lighting when the warehouse is out of power, then LED lamps with integrated emergency power supply are necessary. The control power supply of such lamps can enable emergency mode operation when the mains input is interrupted. At this time, the lamps are powered by batteries, which usually can power the lamps for 90 minutes, but the working power of the lamps is often lower than that of normal operation. It can prevent accidents and chaos caused by power outages, thereby ensuring the safety of personnel in workshops, warehouses or other work areas.

Glare can also cause discomfort and visual fatigue to warehouse workers, and severe cases can cause workers to become disabled and cause accidents. Therefore, anti-glare lamp design and optimized warehouse lighting design (simulation) are important. Usually LED lamps with anti-glare (How to reduce glare in lighting?) diffusers can significantly reduce glare. Similarly, warehouse lighting optimized by lighting simulation is also necessary. ZGSM can provide free lighting simulation to help project parties confirm that the lamp distribution, installation height, and lamp lens (with or without reflector) meet the project's UGR requirements. For more information on optimizing industrial and warehouse lighting, check out our tunable highbay lighting solutions guide.

ZGSM warehouse lighting

ZGSM provides high-performance and durable LED lighting for different industrial sites. Our LED high bay lights (More ZGSM high bay lights) and warehouse luminaires support different installation methods, including bracket mounting, surface mounting, hanging mounting and pipe mounting, etc. They can ensure compatibility with various warehouse structures. Our luminaires offer a wide wattage range, ranging from 100W to 800W. In addition, in order to help users save electricity as much as possible, the product's light efficacy is up to 190lm/W. Durability is another advantage of ZGSM products. For example, our HB13 series withstands high temperature environments (up to 65°C), making it ideal for boiler rooms, foundries and poorly ventilated warehouses. High waterproof, dustproof and anti-collision ratings can ensure the performance reliability of the luminaires in harsh conditions. For high-ceiling warehouses, our asymmetric lenses and 60-120 degree lenses, the former can ensure concentrated light distribution for shelves and work areas, and the latter is suitable for dock area lighting in warehouses. In addition, we also provide optional accessories such as anti-glare covers and emergency backup batteries, the former can reduce glare, and the latter can enable the luminaires to provide uninterrupted safety lighting during power outages. Tunable white (What's tunable white lighting solution?) and adjustable watts are available for some of our high bay lights. ZGSM can also provide free warehouse lighting design (DIALux), which helps to optimize the layout and ensure that the illumination, uniformity (What's light uniformity and how to improve it?) and UGR meet the corresponding standards. The following are the lamps that ZGSM can use for warehouse lighting. If you are interested, you can click to learn more.

Summary

Warehouse lighting plays a vital role in operational efficiency, safety, and energy conservation. Proper lighting ensures accurate inventory handling, reduces workplace accidents, and meets industry standards such as OSHA or IES recommendations. This article explores the key aspects of warehouse lighting, starting with lighting standards (e.g., lux levels in different areas), followed by warehouse lighting designs tailored for two common layouts: rack aisles (which require vertical lighting to identify pallets) and open areas (which require uniform horizontal coverage). In addition, we introduce factors to pay attention to when selecting warehouse lighting, such as different installation methods, different installation accessories including energy-saving motion sensors (Motion sensor in street lighting), emergency power supplies, anti-glare reflectors, high temperature resistance, and high IP/IK ratings. Finally, the guide gives ZGSM solutions, such as high bay lights with emergency power supplies, anti-glare reflectors, tunable white and adjustable watts, and high temperature resistance. By integrating these elements, warehouses can achieve optimized lighting solutions that increase productivity while minimizing energy consumption.

Related Products

Related Blogs

Related Cases

People also ask

Author introduction

Hello Customers,

My name is Taylor Gong, I’m the product manager of ZGSM Tech. I have been in the LED lights industry for more than 13 years. Good at lighting design, street light system configuration, and bidding technology support. Feel free to contact us. I’m happy to provide you with the best service and products.

Email: [email protected] | WhatsApp: +8615068758483