Using LED equivalent chart to replace traditional lamps

Using LED equivalent chart to replace traditional lamps

Introduction

With the growing global push for energy efficiency and sustainability, the shift from traditional lighting solutions to light-emitting diodes (LEDs) is well underway. However, replacing traditional lighting fixtures with LEDs is more than simply swapping one bulb for another. Whether in homes, offices, factories, sports fields, or on the streets, excessively high or low light output, coupled with poor color quality, can lead to unsatisfactory lighting. Among these factors, brightness compatibility is paramount. Brightness here refers to wattage or lumens, meaning we need to determine what wattage or lumen (Watts or lumens?) LED should be used to replace traditional lamps such as incandescent, halogen, fluorescent, and metal halide lamps. This article provides an LED equivalent chart for different traditional lamps to help you understand the differences between CFLs, metal halide lamps, and high-pressure sodium lamps, and LEDs. This LED equivalent chart tells you how much wattage LED will produce the same brightness as a traditional lamp, helping you make a quick decision. In addition, we should also pay attention to the quality of light rather than just the quantity, so it is also necessary to explore key factors such as light distribution, color rendering index (CRI), correlated color temperature (CCT) and lifespan. This can help you make a wise choice that takes into account both performance and efficiency.

Watts to lumens

Generally speaking, the higher the wattage of a lamp, the brighter it will be, but this assumes the lamps use the same light source and have similar other features. For example, incandescent lamps often appear brighter the higher their energy consumption. However, this is no longer the case, as watts are a measure of energy consumption, not the amount of light a lamp produces. LED lamps now use less energy while producing significantly more light than traditional lamps. However, out of habit, many people still use wattage to judge the brightness of a lamp, which is clearly irrational. This relates to luminous efficacy (How to improve luminous efficacy?), which measures the efficiency of converting electrical energy into light energy. LED bulbs (LED lamps) have significantly higher luminous efficacy than traditional bulbs—for example, several times higher than halogen lamps and more than ten times higher than incandescent lamps. Therefore, using wattage to compare the brightness difference between LED and traditional lamps is a misconception. When comparing the brightness of traditional lamps to LED lamps, you need to find an LED lamp with equivalent lumens to determine the appropriate wattage to replace the traditional lamp. Because different lamps have different luminous efficacy, LED equivalent charts have emerged.

Luminous efficiency difference of traditional and LED lamps

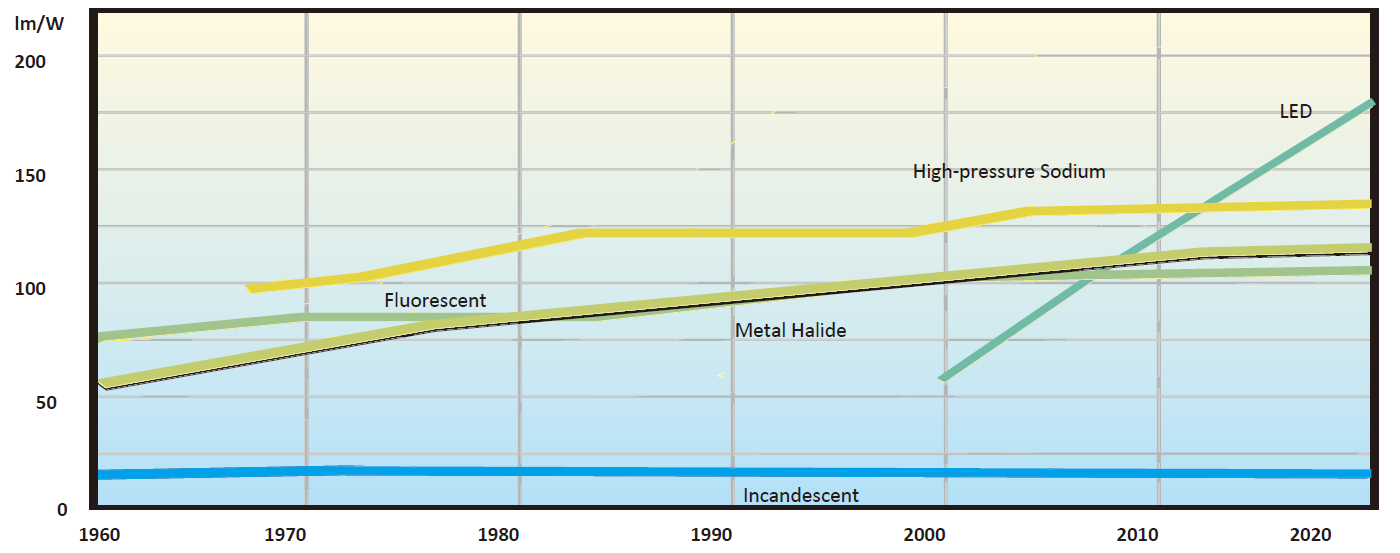

The luminous efficiency of different traditional light sources varies significantly. What’s the reason? It’s because different light sources (Different light sources – LED vs incandescent fluorescent sodium and halogen) use different pathways to convert electrical energy into light. Incandescent lamps rely on thermal radiation. When a tungsten filament is heated to a high temperature, it emits light through thermal radiation, much like lighting a torch. During this process, less than 5% of the electrical energy is converted into visible light, with the remainder wasted as infrared radiation (heat). Consequently, the luminous efficiency is extremely low, typically around 10 lm/W. Gas discharge lamps, including fluorescent lamps, high-pressure sodium lamps, and metal halide lamps, use electrical energy to ionize a gas, generating ultraviolet light. This is then converted into visible light by the phosphor (or the gas itself). Energy loss primarily occurs in the ultraviolet light conversion step, resulting in a moderate luminous efficiency of 50-120 lm/W. LEDs, on the other hand, emit light through electron transitions at a semiconductor PN junction, directly converting electrical energy into visible light. This energy conversion efficiency far exceeds that of other light sources, resulting in the highest luminous efficiency, typically reaching 130-200 lm/W. In fact, LED luminous efficiency wasn’t particularly high initially. However, through optimization of chip materials (such as gallium nitride), packaging technology, and phosphors (What’s phosphors and how LED emits white light?), it has gradually increased from 50 lm/W in the early days to 200 lm/W today, and continues to improve. The following shows the differences in luminous efficiency among different light sources.

We can see that the luminous efficacy of incandescent lamps ranges from 10-15 lm/W, that of high-pressure sodium lamps ranges from 80-130 lm/W, with a median of 110 lm/W, that of metal halide lamps ranges from 60-120 lm/W, with a median of 90 lm/W, that of energy-saving lamps ranges from 75-105 lm/W, with a median of 90 lm/W, and that of LED lamps ranges from 130-190 lm/W, with a median of 160 lm/W. This difference in luminous efficacy is why it’s important to follow a corresponding ratio when replacing these traditional light source fixtures with LEDs. If the total lumens of the original lamp are known, we can also calculate the required wattage of the LED lamp by converting lumens. Below are recommended conversion ratios and the corresponding wattages for common wattages. Note that these are for reference only; in actual applications, the actual wattage depends on the luminous efficacy of the LED lamp you use. In addition, the light distribution (What’s light distribution?), CCT, CRI and other factors of the lamp also need to be considered when replacing.

LED equivalent chart vs different light sources

LED equivalent chart – incandescent vs LED

Assuming the luminous efficacy of an incandescent bulb is 13 lm/W, while the luminous efficacy of an LED bulb is generally around 100 lm/W, with some reaching 120 lm/W. Therefore, a 60W incandescent bulb can be replaced with an 8W LED bulb, achieving a wattage ratio of 1:7.5 (LED vs incandescent). A 100W incandescent bulb can be replaced with a 14W LED bulb, achieving a wattage ratio of 1:7. The following incandescent vs LED equivalent chart is for reference only and the actual lighting needs should be considered when replacing.

| Product type | Wattage of LEDs | Lumen output | Luminous efficacy | Base | Wattage of incandescent | Wattage vs wattage |

| LED bulb | 3 | 300 | 100lm/W | E14 | 25 | 1:8 |

| LED bulb | 5 | 470 | 94lm/W | E27 | 40 | 1:8 |

| LED bulb | 7 | 630 | 90lm/W | E27 | 50 | 1:7 |

| LED bulb | 8 | 800 | 100lm/W | E40 | 60 | 1:7.5 |

| LED bulb | 14 | 1500 | 100lm/W | E40 | 100 | 1:7 |

LED equivalent chart - fluorescent vs LED

Currently, the luminous efficacy of LED tubes is generally around 130 lm/W, with some reaching 150 lm/W. CFLs generally have an efficiency of around 80 lm/W. We can replace lamps based on this efficiency ratio. For example, a 25W CFL tube can be replaced with a 14W 142 lm/W LED tube, achieving a wattage ratio of 1:1.8. Similarly, a 40W CFL tube can be replaced with a 24W ultra-high-efficiency (150 lm/W) LED tube, achieving a wattage ratio of 1:1.7. The following fluorescent vs LED equivalent chart shows luminous efficacy between 131 and 150 lm/W. If your lamp has a lower efficiency, the replacement ratio should be increased accordingly. This chart is for reference only, in the real application your lighting requirements should be met when considering the replacing wattage.

| Product type | Wattage of LEDs | Lumen output | Luminous efficacy | Base | Wattage of Fluorescent lamps | Wattage vs wattage |

| LED tube | 8 | 1050 | 131lm/W | T5 | 13 | 1:1.6 |

| LED tube | 12 | 1575 | 131lm/W | T8 | 17 | 1:1.4 |

| LED tube | 14 | 2100 | 150lm/W | T8 | 25 | 1:1.8 |

| LED tube | 20 | 2900 | 145lm/w | T8 | 32 | 1:1.6 |

| LED tube | 24 | 3400 | 142lm/w | T8 | 40 | 1:1.7 |

| LED tube | 36 | 5200 | 144lm/w | T5 | 54.1 | 1:1.5 |

LED equivalent chart – metal halide or HPS vs LED

A similar method can be used to calculate equivalent wattage for metal halide and high-pressure sodium lamps. Below are the metal halide vs LED equivalent chart and the HPS vs LED equivalent chart. The replacement rate for both is slightly higher than that for CFLs because the luminous efficacy of metal halide and high-pressure sodium lamps is slightly higher than that of CFLs. Furthermore, LED lamps in these applications focus on light distribution, which is superior to traditional lamps, resulting in better lighting effects. This factor is generally not considered when replacing CFLs with LED tubes. For example, a 250W metal halide lamp and high-pressure sodium lamp can produce a total lumen of 20,000lm and 28,500lm, respectively, but we use 115-120W LED lamps to replace them because the light distribution of traditional lamps is less reasonable than that of LEDs. If you are interested in the following LED retrofits and LED street lighting, click on the LED product to learn more.

| Product type | Wattage of LEDs | Lumen output | Luminous efficacy | Base | Wattage of metal halide | Wattage vs wattage |

| LED retrofit | 18-27 | 2300-3500 | 131lm/W | E26/E40 | 50 | 1:2.3 |

| LED retrofit | 27-36 | 3500-5400 | 131lm/W | E26/E40 | 70 | 1:2.2 |

| LED retrofit | 36-45 | 5000-6700 | 150lm/W | E26/E40 | 100 | 1:2.5 |

| LED retrofit | 80 | 12000 | 145lm/w | E26/E40 | 150 | 1:1.9 |

| LED retrofit | 115 | 18000 | 142lm/w | E26/E40 | 250 | 1:2.2 |

| LED retrofit | 150-200 | 24000-30000 | 144lm/w | E26/E40 | 400 | 1:2.3 |

| Product type | Wattage of LEDs | Lumen output | Luminous efficacy | Base | Wattage of metal halide | Wattage vs wattage |

| LED street light | 40 | 6000 | 131lm/W | / | 70 | 1:1.75 |

| LED street light | 60 | 9000 | 150lm/W | / | 100 | 1:1.7 |

| LED street light | 80 | 12000 | 145lm/w | / | 150 | 1:1.9 |

| LED street light | 100 | 15000 | 142lm/w | / | 200 | 1:2 |

| LED street light | 120 | 18000 | 144lm/w | / | 250 | 1:2.1 |

| LED street light | 200 | 30000 | 144lm/w | / | 400 | 1:2 |

Light quality over quantity

In practical applications, luminous efficacy (luminous flux) is not the only selection criterion. For example, light distribution, color rendering index, and lifetime must also be considered in conjunction with the specific application scenario to make a comprehensive judgment.

Light distribution

Traditional light sources such as metal halide lamps, high-pressure sodium lamps, fluorescent lamps, and incandescent lamps are all omnidirectional light sources that emit light in all directions. They perform reasonably well for residential lighting. However, in warehouse, sports field, and road lighting applications, these light sources often require reflectors to concentrate the light and direct it toward the desired illumination area. However, during the reflection process, light undergoes multiple internal reflections, leading to brightness loss. For example, in metal halide lamps, this process can result in a loss of up to 30% of the total lumens. When using directional light sources, the required number of lumens is reduced. LED light sources are inherently directional, with a light emission angle of 180 degrees, unlike the 360-degree angle of traditional light sources. Additionally, the lenses in LED fixtures can redistribute this portion of the light flux. For example, in sports field lighting, lenses are often used to concentrate the light beam within a 30-degree or smaller beam angle to illuminate a specific corner of the field. In road lighting, the secondary light distribution (More about street light distribution) of lenses allows a single streetlight to illuminate a wide and long stretch of road, unlike residential garden lights, which only illuminate a small area directly below the fixture.

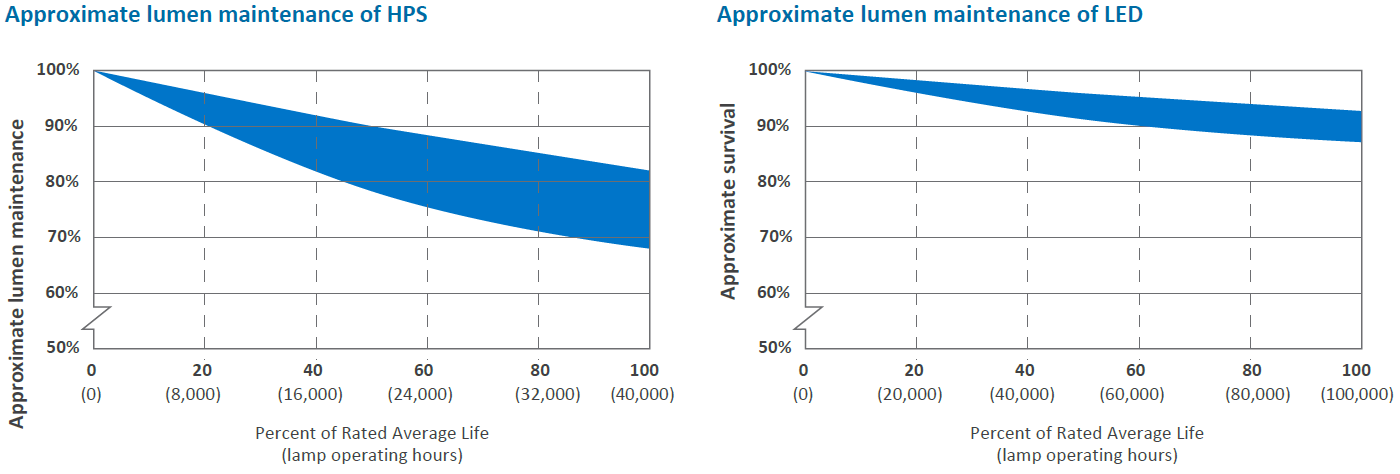

Lifetime

The lifespan of incandescent bulbs is only around 1,000 hours. In the 1990s, we all had to replace these bulbs every year or two. The reason is that incandescent bulbs generate a lot of heat, causing the tungsten filament to melt. High-pressure sodium lamps, metal halide lamps, and energy-saving lamps also have similar issues. Taking high-pressure sodium lamps as an example, the process of arc discharge exciting sodium vapor to emit light occurs in a high-temperature, high-pressure environment. Extreme high temperatures can damage the material of the arc tube. Additionally, high temperatures cause electrodes to wear out due to sputtering, and the strong chemical activity of sodium vapor corrodes the electrodes and tube walls, thereby affecting luminous efficiency and light transmission. Furthermore, the ballast may malfunction due to high temperatures, thereby affecting the lifespan of the lighting fixture. LED lighting fixtures perform exceptionally well in this regard. First, current technology can convert 60-70% of electrical energy into light energy, reducing thermal loss while also providing better heat dissipation. Additionally, high-quality switching power supplies ensure stable DC output to power the LEDs. However, when selecting LED lighting fixtures, it is essential to verify that the manufacturer uses high-quality power supplies (which is also called LED drivers) and that the fixture design ensures efficient heat dissipation to mitigate light decay (What's light decay?). Otherwise, you may encounter issues such as severe light decay, flickering, or even complete shutdown. In such cases, you would have to incur the expense of replacing the LED driver or the entire fixture, a process that is not only cumbersome but also requires a significant financial investment.

CRI and luminous efficacy

When replacing traditional lighting fixtures with LED lighting, color rendering is an issue that must be given serious consideration. It determines the ability of the light source (fixture) to accurately reproduce the true colors of objects. Its value ranges from 0 to 100, with natural light having a CRI of 100, and incandescent lamps, which have a CRI close to natural light, are also considered to have a CRI of 100. Therefore, when replacing incandescent lamps with LED fixtures, you must ensure that the LED fixtures' color rendering performance meets the lighting requirements. When replacing high-pressure sodium streetlights with LED streetlights, since the former has inherently lower color rendering, there is little need to consider the impact of color rendering when switching to LED, as the latter typically achieves better results (generally exceeding CRI 70). Additionally, when replacing metal halide lamps used in sports fields with LED sports field lights (ZGSM LED sports lights), we must pay special attention to the difference in color rendering between the two. The former often has a higher color rendering index, even reaching 90, so when replacing them, we need to use LED sports field lights with a CRI of 90 to meet the requirements of spectators, athletes, and cameras for high color rendering. If conditions permit, it is advisable to select LED fixtures with high luminous efficiency for replacement, as this can significantly reduce operational costs (electricity costs) in the long term.

Using LED retrofit kit

When replacing traditional lighting fixtures with LED lighting, customers sometimes do not want to remove the original fixture housing and instead only wish to replace the core components with LED modules. In such cases, LED retrofits can be an excellent option. Additionally, we can use an LED equivalent chart to calculate the wattage of the LED module. Furthermore, we must ensure that the structure meets the required specifications, including dimensions, waterproofing, and installation requirements. Fortunately, ZGSM offers a mature solution: the ST25 LED retrofit kit. It comes in two types—square and round—with a range of products featuring different wattages, color temperatures, and lenses to choose from. It can meet the replacement needs of most traditional lighting fixtures, including globe post tops, bell post tops or bell pendants, and rectangular post top lanterns. For ease of installation, we can also customize the kit based on the customer's traditional lamps to address installation and waterproof issues. The benefits are clear: customers enjoy the high luminous efficiency and uniform lighting of LED technology while avoiding the issues associated with removing old equipment, thereby preserving the original appearance of historical buildings. Since this is a customized product, the actual replacement cost must also be considered; if the quantity is small, the cost may be higher.

Summary

LED lighting fixtures, with their advantages of high efficiency, energy savings, and long lifespan, are gradually replacing traditional lighting technologies. During the replacement process, LED fixtures and traditional fixtures are not simply replaced on a one-to-one basis, as there are significant differences in their luminous efficacy. This article provides an LED equivalent chart for reference when converting from traditional light sources (incandescent bulbs, halogen lamps, fluorescent lamps, high-pressure sodium lamps, etc.) to LED lighting. For example, a 50W incandescent bulb has a total luminous flux of approximately 500 lumens, so a 5W LED fixture can be used as a replacement. Similarly, a 400W high-pressure sodium lamp can be replaced with a 150W LED lighting fixture. Additionally, ZGSM emphasizes that the quality of light emitted by the fixture is equally important. Key indicators related to light quality include light distribution, color rendering index, and lifespan (How long do LED lights last?). For instance, more reasonable light distribution often allows for a lower wattage LED fixture, while a longer fixture lifespan reduces maintenance costs in the long run. Furthermore, to address installation challenges during actual replacements, ZGSM's LED retrofit kit offers an efficient solution. Its customizable modules (ST25 LED retrofit kit) can be directly embedded into the existing fixture housing, allowing users to enjoy the energy savings and high-quality lighting of LED upgrades while preserving the architectural aesthetics. For more information, please contact ZGSM to obtain further details.

Related Products

Related Blogs

Related Cases

People also ask

Author introduction

Hello Customers,

My name is Taylor Gong, I’m the product manager of ZGSM Tech. I have been in the LED lights industry for more than 13 years. Good at lighting design, street light system configuration, and bidding technology support. Feel free to contact us. I’m happy to provide you with the best service and products.

Email: [email protected] | WhatsApp: +8615068758483