How to prevent the occurrence of purple street light?

How to prevent the occurrence of purple street light?

Introduction

In the 21st century, cities and towns around the world began to switch from sodium lamps to LEDs for street lighting, which also changed the color of many nighttime roads from yellow to bright white. However, in recent years, there have been reports that local street lights have emitted a strange purple color, such as Vancouver, Canada, Schaumburg, Illinois, Ireland and other states in the United States. This unexpected purple color has raised concerns about the impact on the safety of drivers and pedestrians at night because it changes the way people perceive their surroundings at night. The current mainstream view is that the degradation of LED phosphors has caused LED lamps (More ZGSM LED products) that originally emitted white light to now emit purple light. ZGSM also believes that this explanation is more reasonable. To help everyone understand, we will also focus on explaining why LEDs emit white light, the cause of purple street light (phosphor degradation), whether these purple-emitting LED lamps are harmful, and how we as related companies should avoid this situation (purple street light).

How does white LED street light work?

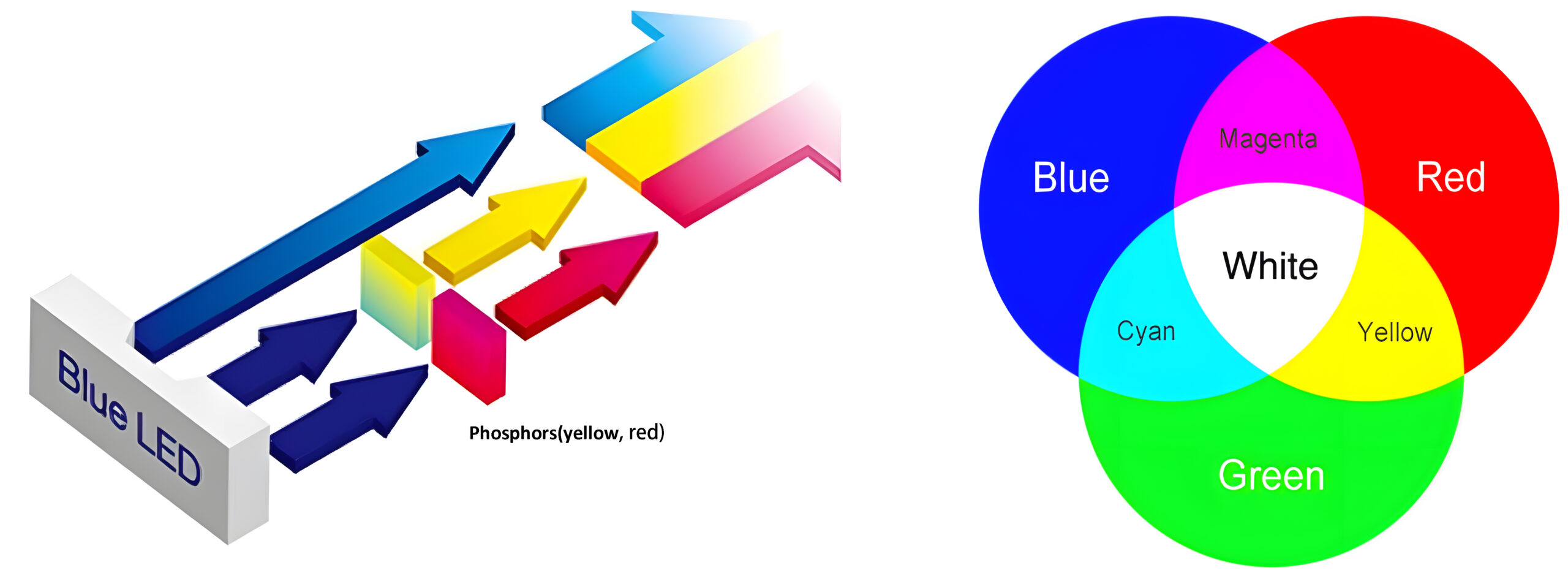

Light-emitting diodes are one of the most energy-efficient lighting technologies currently in existence. In addition, LEDs have many advantages over other types of lighting, including long life (How long LEDs last?), good heat dissipation, and the light they produce is of equal or better quality. In fact, diodes do not emit white light themselves. They can actually emit pure colors such as red, green, yellow, and blue. These lights often have different wavelengths. LED white light lighting is white light formed by mixing different wavelengths of light together just like sunshine. There are currently two mainstream methods to produce white light. One is to integrate tiny light-emitting diodes that emit red, green (or yellow), and blue light into a large device, and then mix them in a certain proportion to emit white light. Another method is to use only blue light-emitting diodes, but we also need to cover the surface of the lamp chips with phosphors. When the blue light emitted by the blue diode passes through this layer of fluorescent material, the phosphors will absorb part of the blue light wavelength and release red and yellow light. In this way, the three (the blue light itself, and the red and yellow light formed later) form a mixture of colors, that is, the blue light-emitting diode + fluorescent material presents white light again. The former has a good application in OLED displays and color-changing bulbs, while the latter is mostly used in LCD and lighting industries.

The main reason causes purple grow

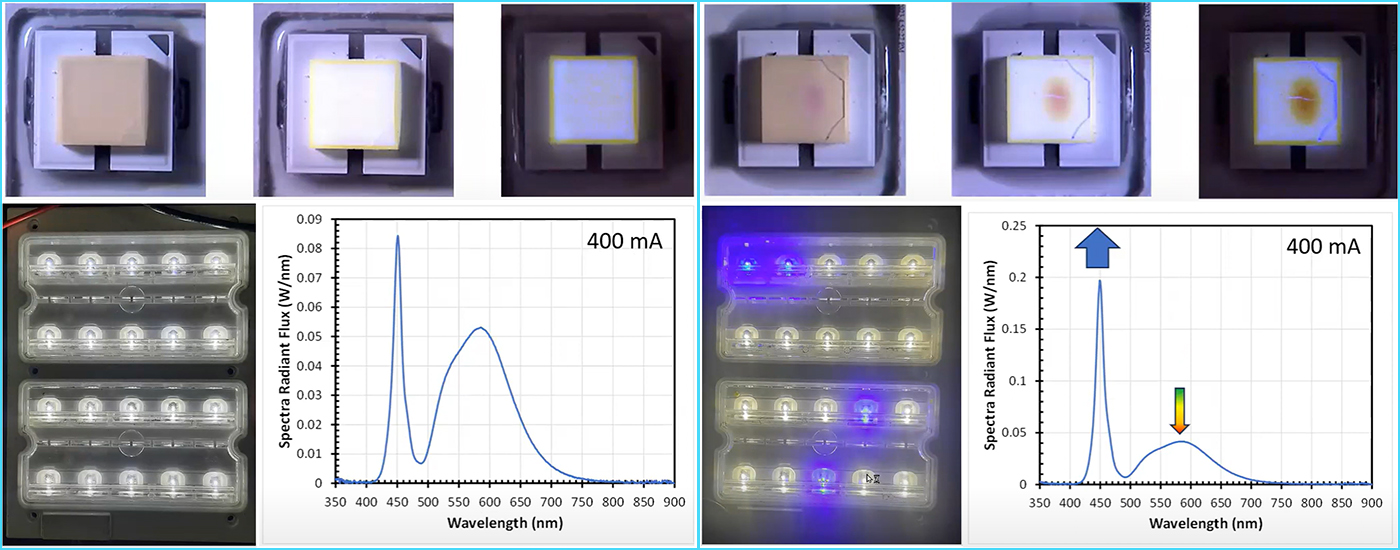

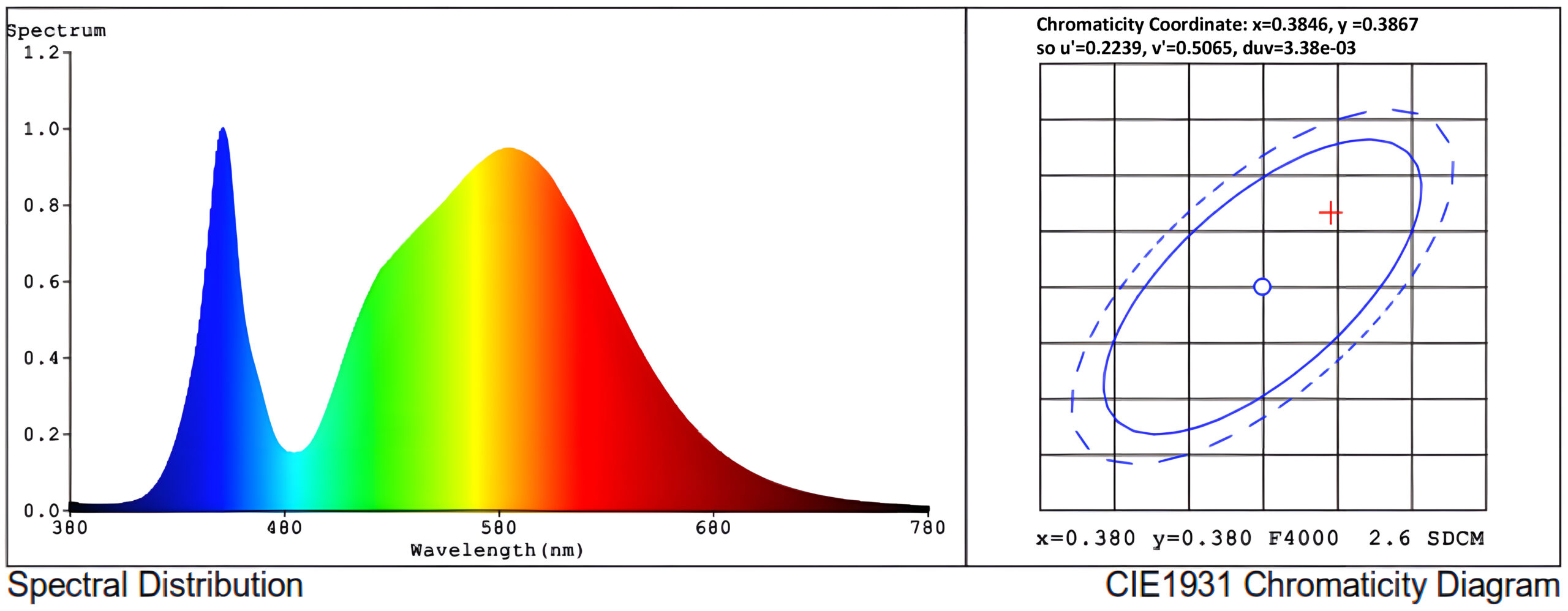

A research institute has conducted a special study on this phenomenon. They observed LED street lamps that emit purple or blue light. When these purple street lamps are driven by a current of 15uA, the study found that not all LEDs in the same street lamp emit purple and blue light. Only some LEDs emit abnormal purple and blue light. These abnormal LED chips may have fine cracks in their phosphor layers, or the phosphor layers are separated from the LED chips, or in severe cases, the LED chips are completely exposed. Under naked eye observation, only the third case can clearly observe purple/blue light. The laboratory measured the color deviation. When observed with the naked eye, the normal LED has a delta u’v’ = 0.009 relative to 4,000 K, while the abnormal LEDs have a delta u’v’ = 0.095 relative to 4,000 K, which is much higher than the normal level. In addition, the spectral power distribution (What’s spectral power distribution?) of LEDs emitting purple and blue light also changes significantly compared to conventional LEDs (4000K). The blue light emission is significantly increased, while the phosphor emission peak (yellow and green wavelengths of light) is significantly reduced. See the figure below for details.

From the above results, we can conclude that the direct reason for LED street lamps to emit purple light is that the phosphor layer has cracks, peeling or even detachment. So what is the deep-seated reason for this phenomenon? The current mainstream view is that there is a problem with the bonding between the LED chip and the phosphor layer (fluorescent coating). They all agree that the bonding between the LED chip and the silicone-phosphor layer(phosphor layer) will gradually decrease over time. This decrease in bonding is manifested as the silicone adhesive becoming brittle, which will cause the phosphor layer to separate from the LED chip (that is, the separation of the phosphor coating from the LED chip). Intuitive signs of this damage include visible cracks and even severe fractures in severe cases. When the phosphor layer is completely missing or detached, the LED will only emit blue light because this blue light no longer passes through the phosphor coating to emit the full-spectrum white light required by its design. In addition, there are some non-mainstream views that other factors also play a synergistic role, such as internal heat accumulation, repeated vibrations caused by frequent vehicle passing, and gravity factors. However, for the same lamp, some LED chips (More about LED chips) emit blue-violet light, while others do not, and there is no regularity. ZGSM believes that it has little to do with these factors. The fundamental reason is that defects in the phosphor coating or poor manufacturing process lead to the detachment of the phosphor layer, which in turn causes the LED chips to lose the ability to convert blue light into yellow and red light. Other deeper reasons can only be left to researchers for further study.

How does the purple light affect vision?

Purple light/blue light is generally only used as an atmosphere light. When you are suddenly in a road lighting covered by purple light, you can hardly see things on the road. One reason is the reduced illumination, and the other is the visual discomfort caused by purple light. But what is more worrying is that this light will change the ability of drivers and pedestrians to perceive the surrounding environment, which will make people feel uneasy. The following are the adverse effects of purple street lights in ZGSM’s opinion.

1. Purple street lights are not conducive to the safety of drivers and pedestrians. The reason is that LED street lights that have lost the fluorescent layer have lost the ability to convert blue light into green and red light, and the human eye has a higher photopic sensitivity to the latter two lights, which reduces the light flux of street lights. This change makes the road lighting that originally complies with ANSI/IES RP-8 and EN13201 no longer meet the corresponding road lighting design standards (About road lighting design). The personal safety of pedestrians and drivers under such lighting can be imagined.

2. Highly saturated blue and purple light will weaken people’s ability to see details because there are no cells sensitive to blue in the center of the retina. In addition, the high proportion of blue light in street lamps is also harmful to human health. This is because blue light inhibits the secretion of melatonin, interferes with the human body clock, and causes insomnia, headaches and anxiety. Blue light also interferes with the ecosystem. Insects, birds and reptiles are sensitive to blue-violet light. They will be attracted to purple street lights, which will affect their foraging, mating and migration.

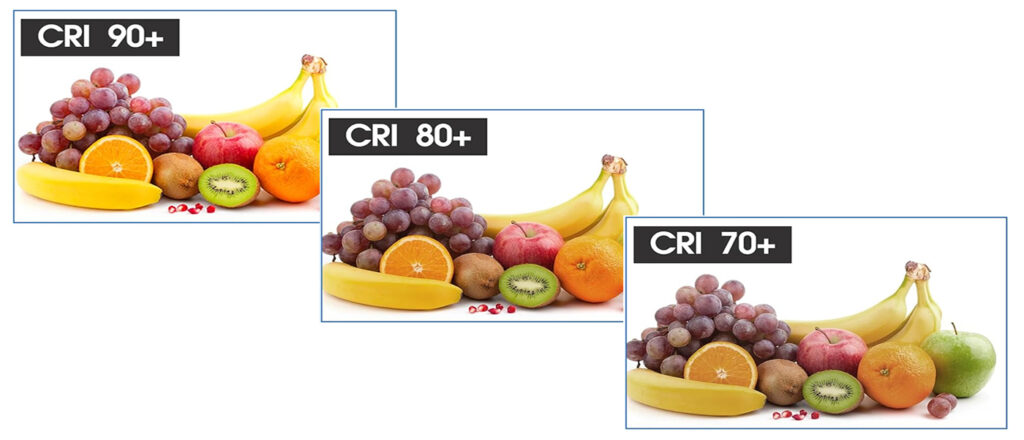

3. Adequate color reproduction of outdoor lighting is an important factor for drivers and pedestrians to identify objects. Purple street lights often lack green, red and yellow light in their spectrum, which will result in a low CRI (CRI vs luminous efficacy) for such street lamps. When the color reproduction decreases and the contrast changes, the light of these purple street lights will also affect road and pedestrian safety. If you want to learn more about CRI vs luminaire efficacy, click to view more information.

LM80 and ENEC+ to prevent purple street light

ZGSM recommends that street light manufacturers comply with relevant testing standards, such as LM80, when selecting LED chips to prevent early LED damage in the future. If conditions permit, you can also apply for IEC62722 report + ENEC+ certification (More ENEC+). We recommend that the operating current and operating voltage of the actual lamp should be less than the LED operating current and temperature tested in the LM-80 report. Complying with this principle can ensure that the test conditions accurately reflect the operating pressure faced by the LED in actual applications, thereby more reliably indicating the long-term performance and stability of the LED street light in use. The IEC62722 and ENEC+ reports can reflect the color shift of the lamp after a certain period of time, and the test time is usually 6000 hours. Below we focus on what LM80 and ENEC+ are.

LM80

LM80 is an LED chips test method approved by Energy Star in the United States, which is used to evaluate the lumen maintenance and color change of LED light sources. In the LM80 test, the LED light source will be tested for at least 6000 hours under different temperature conditions. The lumen maintenance and chromaticity coordinates at each time point (1000 hours as a time point) can be obtained through testing. In daily applications, manufacturers tend to pay more attention to lumen maintenance (Lumen maintenance and maintenance factor) and ignore the result of color shift. In order to prevent the generation of purple street light, we need to pay attention to this color change. The LM80 test report records the chromaticity coordinates on the CIE 1976 color space diagram to analyze the color change, namely color shift. Generally speaking, the industry considers Au’V≤0.007 to be acceptable, that is, the color change cannot be observed by the naked eye. ZGSM lamps usually use Lumileds 3030 or 5050 LED chips, which have undergone rigorous testing. At the same time, the Ts temperature and operating current of our lamps also meet the requirements of LM80, which ensures that the color shift of the lamps meets the corresponding requirements in actual applications.

ENEC+

ENEC+ is a European certification mark, which is a voluntary certification. The test content includes the electrical parameters of the lamp, light intensity distribution, color temperature, CRI and chromaticity coordinate, etc. The last point is about the color shift of the street light. When checking ZGSM’s ENEC+ certification, we can see the integrating sphere photometric test data. Taking ZGSM’s 100W Rifle street light (ZGSM Rifles series streetlights) as an example, its chromaticity coordinate after 6000 hours of testing is x=0.3846, y=0.3867, and then we can get u’=0.2239, v’=0.5065. By comparing with the standard 4000K color temperature light source F4000, we can get the duv result. In ZGSM’s ENEC+ report, we see that the test result is duv=0.000338, which is in line with expectations. Below are ZGSM’s Rifle and Falcon series street lights that have passed ENEC+ certification, as well as some other street light products, which used LM80 tested LED chips.

Summary

LED street lights have been in use for nearly 20 years, and the phenomenon of purple street lights has also been a topic of great concern in the LED industry in recent years. Through the study of the main text, we know that white LED street lights produce white light through the interaction of blue chips and phosphors. However, after a period of use, the phosphor layer (fluorescent coating) of LED chips cracks and falls off due to various reasons (mainly manufacturing process defects), causing the proportion of blue light emitted by the LED to increase and present purple light. We also point out the negative impact of such purple street lights, which affects the urban landscape and may also bring safety hazards. The main reason is that the luminous flux (Lumens vs Watts) and and CRI of the purple street light have changed significantly compared with the initial state, which is not conducive to drivers and pedestrians observing road conditions. In order to effectively prevent this from happening, ZGSM believes that the LED chips used in LED street lights must be strictly tested by LM80 to prove that their color shift meets the requirements. At the same time, qualified suppliers can apply for ENEC + certification to prove that the color changes of these lamps after a period of use are within the specified range. If you are interested in more relevant information, you can contact ZGSM for more relevant information.

Related Products

Related Blogs

Related Cases

People also ask

Author introduction

Hello Customers,

My name is Taylor Gong, I’m the product manager of ZGSM Tech. I have been in the LED lights industry for more than 13 years. Good at lighting design, street light system configuration, and bidding technology support. Feel free to contact us. I’m happy to provide you with the best service and products.

Email: [email protected] | WhatsApp: +8615068758483