Something you should know about different types of LEDs – SMD vs COB

Something you should know about different types of LEDs – SMD vs COB

Introduction

A light-emitting diode is a semiconductor light source that emits light when an electric current flows through it. It is commonly known as LED and plays an important role in our daily life. LEDs do many different jobs in a variety of devices such as LED light, LED display, LED traffic light, etc. Hope that we can give you an understanding of the classification (type), advantages, and applications of LEDs through this article.

Type of LEDs

According to the difference of LED chip packages, the various types of LEDs include SMD vs COB, MCOB, and MCCOB.

What’s SMD LEDs?

SMD is short for Surface mounted diode which is a standalone chip on a ceramic base. They are manufactured by attaching the light-emitting diode chip to the surface of the printed circuit board (PCB) through surface mount technology (SMT). A distinctive feature of SMD chips is the number of connection points and diodes. In SMD lamps, you can find more than three diodes and more than two contact points. It can be used for white LED lamps and LED strip lights. Now it’s very common in light industrial applications such as street light, floodlight, and linear light.

SMD is short for Surface mounted diode which is a standalone chip on a ceramic base. It can be used for white LED lamps and LED strip lights. Now it’s very common in light industrial applications such as street light, floodlight, and linear light.

What’s COB LEDs?

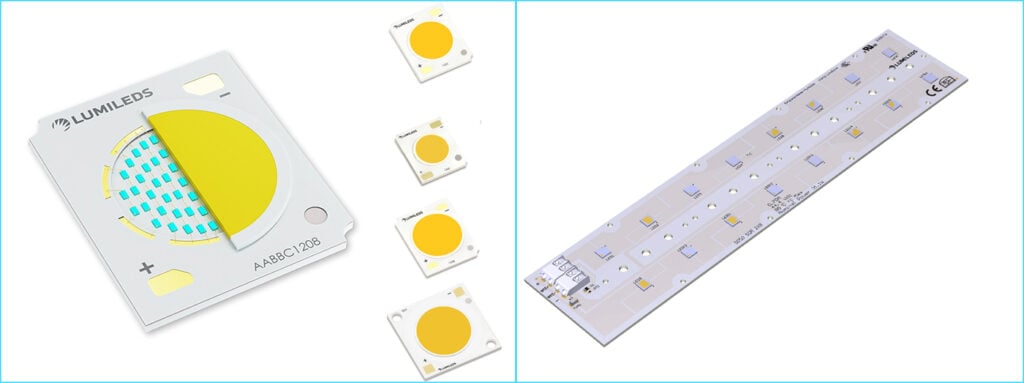

COB is short for chip on board. COB (Chip on Board) is an LED chip that is in direct contact with a substrate (such as silicon carbide, ceramic or metal substrate). The chips in a COB are often closely arranged together, and multiple diodes (usually 9 or more) are integrated into the printed circuit board of the COB. These chips are often arranged in a characteristic series-parallel manner, with 2 circuit contact points on the outside. This kind of LED comes as a high-powered chip that is wired on a printed circuit board with optimal thermal management. It’s normally used in LED downlight, LED tracking lights.

Except for SMD vs COB, MCOB and MCCOB are becoming common in LED lighting application now.

MCOB is short for multiple chips onboard LED. They are multiple COB LEDs integrated to form a single chip. This technology is used in LED bulbs and tubes. MCCOB is short for multiple chips and cups on board. They are normally used for high bay fixtures and some floodlights.

As we introduced before, we can divide the LEDs mainly into SMD, COB, MCOB, and MCCOB based on the different structures of LEDs. However, LEDs can be divided into three different categories according to their power. It includes Low-Power, Mid-Power, and High-Power.

Power is found mathematically by forwarding voltage and drive current. For example, Lumileds 3030 LEDs with 5.8V consumes approximately 0.7W when driven with a current of 120 mA.

As Lumileds said, they classified with the standard as follows. LEDs with power below 0.1W in the Low-Power class. LEDs with a power range of 0.1W to 1.0W are known as Mid-Power, while those with a power range of 1W to 3W are known as High-Power LEDs.

But different supplier has a different standard. Osram told us, LEDs with power below 0.2W are called Low-Power. LEDs with power between 0.2W and 1.0W are called Mid-Power. And LEDs with power between 1.0W and 4.0W are called High-Power. For 4W LED chips of Cree, they still called it Mid-Power.

Advantages and disadvantages of SMD vs COB LEDs.

Based on different standards, the Type of LEDs can be SMD, COB, or others. Here mainly introduces the advantages and disadvantages of SMD vs COB.

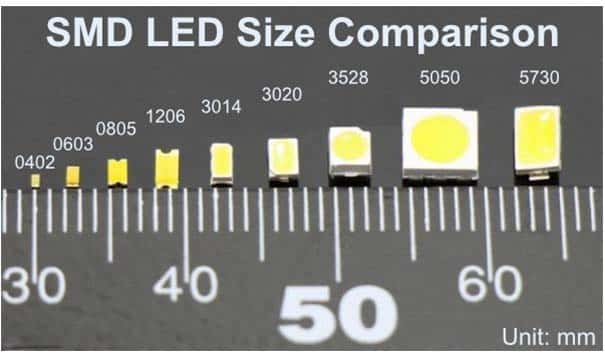

SMD refers to the term “Surface Mounted Device” LEDs, which are the utmost shared LEDs in the market. There are multiple sizes of SMD LED chips: 2835, 3535, 3030, 3014, 5050, 5630; they are termed according to their dimensions: length and width. For instance, the size of the 3535 is 3.5 x 3.5mm, 3030 is 3.0 x 3.0mm, 5050 is 5.0 x 5.0mm. Below are the advantages and disadvantages.

Advantages of SMD LEDs

- SMDs are more efficient than COBs because the light source produces higher lumens per watt, which means that they produce more light with a lower wattage.

- They produce a wider beam of light which is spread over a greater area. This means that less material is needed for the heat sink, which in turn means that they are more economical.

- SMD lamps produce a wide spread of light which is suitable for area lighting.

- Since there are many chips on one PCB, as time went by, if one of the chips is broken, the other LED chips will still work by designing a special circuit.

- High reliability, strong vibration resistance, and low defect rate in solder joint points.

- Because SMD LEDs are with relatively small size and have less weight, it’s easy to achieve automation, which improves production efficiency. Then materials, energy, equipment, manpower, time, will also be saved.

- With small size SMD LEDs, it makes SMD LEDs more flexible in lamp design. And with less weight and good heat dissipation (less heatsink), the lamps are with lower weight which is competitive in some tender and also good for safety. Due to their power limitations, class 2 electrical are considered safe from a fire initiation point of view and provide acceptable protection against electric shock. Therefore, it is recommended to choose class 2 electrical for outdoor lighting.

Disadvantages of SMD LEDs

The manufacturing procedure to make SMD is more expensive because the SMD diodes (LED chips) are machine printed on a PCB board.

COB is the short form of “Chip on Board”. Manifold LED chips are packed together as a single lighting module and it looks like a panel when it lights up. Different from SMD, COB has more diodes. COB has a printed circuit board on its substrate and diode chips are arranged in parallel or/and in series, based on the circuit of the PCB. The substrate can be either in aluminum or ceramic. Below are the advantages and disadvantages.

Advantages of COB LEDs

- Cheap

- As COB LED chip is placed on the printed circuit board, and the electrical connection between the chip and the substrate is realized by a wire stitching method, and is covered with a resin. So reliability is insured.

- With relative high CRI and uniformity lighting COB is suitable for indoor lighting.

- COB is easy for installation and use. These reduce the difficulty of lamp design and save lamp assembling cost.

Disadvantages of COB LEDs

- As the single cluster of LED’s are mounted in one point, they require greater cooling, so a larger heat sink, usually made of aluminum, must be mounted to dissipate the heat. As more material is required to manufacture a COB LED heat sink, this usually increases the cost. But even using more materials, the dissipation problem of COB can still not be solved.

- Comparing to SMD, COB has more LEDs at same area as SMD, so it has the disadvantage like spotlight and glare. But with special cover and plus its uniformity lighting, it’s also well used in indoor lighting.

- Few street lights with COB LEDs are with modular design, this makes COB street light are not easy for maintenance. Additionally, if one COB fails, the power of lamps will greatly reduce and then we have to maintenance this lamp.

Applications of SMD vs COB LEDs

SMD LEDs are one of the most common types of lighting that we have today. They are used in many outdoor applications like street lights, floodlights, high bay lights, canopy lights, linear lights.

COB LED lights are used in numerous applications, including COB street lighting, tracking light, downlight, spotlight, and low bay light.

So, their application scenarios are not fixed. For example, Both COB and SMD can be used in street lighting and high bay light. While COB is much common in downlight and tracking light, and SMD are much common high bay light, street lighting.

ZGSM has different kinds of LED lights, which includes street lights, flood lights, high bay lights, canopy lights and sports lights. These lights are all used SMD LEDs which make these light has advantages like high efficiency, multiple light distributions and long lifetime (good heat heatsink). For examples, ZGSM LED street lights can either go with mid-power 3030 and high-power 5050 SMD LEDs, ZGSM high bay lights can be with either 2835 or 3030 SMD LEDs. ZGSM flood and sports can be with either 3030, 5050 and 3737 SMD LEDs. If you are interested in our LED light, please click below links to find more.

Summary

Below we listed the differences between SMD vs COB. But it will certainly be as below. For example, some COB LEDs are with high efficient than SMD LEDs. Or SMD will be a cheaper solution which is used in street light applications. Or even a downlight with COB can get a better performance in heat dissipation.

| SMD LED lights | COB LED lights | |

|---|---|---|

| Number of diodes | Normally up to 3 or 4 diodes | Multiple diodes, 9 or more |

| Appearance | Small, looks like a whole unit | Big, diodes sometimes are visible |

| Quality of light | Wide beam angle with some glare. | Relatively high CRI and uniformity lighting |

| Lumens per watt ratio | Normally higher than COB | Relatively lower efficiency |

| Size of the heat sink | Small heat sink | Need a big heat sink |

| Technology | They require mounting then reflow soldering on the PCB | It does not require any mounting or reflow soldering |

| Manufacturing costs | Relatively high | Relatively low |

Related Products

Related Blogs

Related Cases

People also ask

Author introduction

Hello Customers,

My name is Taylor Gong, I’m the product manager of ZGSM Tech. I have been in the LED lights industry for more than 13 years. Good at lighting design, street light system configuration, and bidding technology support. Feel free to contact us. I’m happy to provide you with the best service and products.

Email: [email protected] | WhatsApp: +8615068758483