Vibration resistance of LED light – ANSI C136.31 vibration test

Vibration resistance of LED light – ANSI C136.31 vibration test

Introduction

LED lighting fixtures feature high luminous efficacy (What’s luminous efficacy and how to increase it?), low energy consumption, and extended service life, leading to their widespread adoption globally. Despite their robust performance, environmental factors can still impact their practical application and shorten their operational lifespan. Harsh environments compromise fixture reliability, exemplified by the well-known IP rating and IK rating, which respectively indicate dust and water resistance and impact resistance. Additionally, streetlights and floodlights mounted on roads and bridges endure vibrations that can damage housings and disrupt normal illumination. Some vibrations originate from traffic, transmitted through roads, bridges, or overpasses to the fixtures. Others result from wind-induced oscillations of poles and brackets, which then transfer vibrations to the luminaires. So what certifications and tests prove luminaires can withstand such installation environments? The answer is vibration testing—a critical factor in assessing LED luminaire reliability that has gained traction in numerous streetlight projects in recent years. This article explains what vibration testing entails, relevant testing standards, key testing aspects, and more. Let’s dive in to explore LED luminaire vibration resistance in depth.

Why go with vibration test?

Vibration testing of LED luminaires primarily aims to simulate the mechanical environments encountered in real-world applications. This process identifies potential flaws in product design, structure, or manufacturing processes early on, ensuring safety, reliability, and consistent performance throughout the product’s entire lifecycle. Specifically, it simulates the violent vibrations experienced during transportation to prevent damage upon shipment. Additionally, it addresses the vibrational stresses encountered during installation to guarantee long-term operational safety.

Simulating vibration during transportation

In fact, LEDs exhibit significantly greater resistance to vibration during transportation than traditional lighting fixtures, a property determined by their structural design. A light-emitting diode (LEDs and more about LED chips) is a semiconductor device composed of an n-type semiconductor and a p-type semiconductor placed side by side. When current flows through these devices, electrons and holes recombine within the device, generating light output corresponding to the energy of the semiconductor’s bandgap. The light-emitting diode is secured to a mounting bracket with adhesive and then connected to the circuit board via wires. Finally, the LED is encapsulated with epoxy resin to seal and protect the electronic components. This filament-free design grants LED lighting superior shock and vibration resistance during transportation. While such vibration testing is not the primary focus of this article, ZGSM possesses relevant testing equipment for such evaluations, as illustrated below.

Simulating vibration after installation

LED luminaires in various installation scenarios are continuously subjected to vibrations at specific frequencies. For instance, fixtures mounted on roads and in tunnels experience vibrations when vehicles pass by, which are transmitted through the road, bridge, or tunnel structure to the lighting system. Similarly, sports lights (ZGSM sports lighting solutions) and floodlights mounted on tall poles vibrate due to wind, with the vibration amplitude depending on the pole system’s dimensions, shape, stiffness, and damping characteristics. The EN 60068-2-6 and ANSI C136.31 vibration tests simulate these vibrations to determine whether luminaires can withstand potential vibration conditions in normal installation environments. This mechanical performance test aims to simulate the durability (service life) of luminaires (including LED luminaires) within a relatively short timeframe.

What are the standards for vibration testing?

To ensure the safety of electronic equipment in vibration environments, numerous vibration testing standards apply. So, what are the relevant vibration resistance standards for LED lamps? As ZGSM knows, standards related to LED lamps and luminaires include IEC60598-1, IEC60068-2-6, ANSI136.31, and GB/T 33721-2017. IEC60598-1 is specific to rough service luminaires, while GB/T 33721-2017 is China’s national standard, and its content is largely similar to IEC60068-2-6. Therefore, this article will focus on these two common standards: IEC60068-2-6 and ANSI136.31.

IEC 60068-2-6 vibration test standard

Vibration testing is primarily divided into sinusoidal and random vibration. IEC has introduced relevant standards, including IEC 60068-2-6, which uses sinusoidal vibration to test lamp performance, and IEC 60068-2-64, which focuses on random vibration testing. Sinusoidal vibration (IEC 60068-2-6) is a frequently used test method to simulate vibrations generated by rotation, pulsation, and oscillation (as found in ships, aircraft, vehicles, and spacecraft), as well as for analyzing product structural resonant frequencies. Applicable products include LED lamps, traditional lamps (About using LED lamps to replace traditional lamps), and various electronic products. The test includes both swept-frequency and fixed-frequency vibration, with the severity of the test depending on the frequency range, amplitude, and test duration. The lamp should operate normally within the test frequency range for a period of time. The 60068-2-6 test report will describe the test frequency and lamp performance.

ANSI C136.31 vibration test standard

ANSI C136.31 is an American national standard coordinated and developed by ANSI (American National Standards Institute and more about ANSI). This standard covers the minimum vibration resistance and vibration test methods for road and area lighting fixtures. However, this standard does not apply to testing methods related to vibration caused by natural or catastrophic disasters. It specifies the minimum vibration resistance of road and area lighting fixtures. Generally, luminaires on bridges or overpasses must withstand 3.0G, while luminaires in other locations must withstand 1.5G. It provides detailed instructions for test preparation, test parameter confirmation, test execution, and result evaluation. If your product shows no loose parts or damage that could affect the safety and full functionality of the luminaire during the corresponding test (for example, the 1.5G test), it is considered to have passed the 1.5G vibration test.

More about ANSI C136.31 vibration test

ANSI C136.31 specifies detailed vibration testing methods for road and area lighting fixtures (ZGSM street light and area lighting solutions), aiming to verify their structural integrity and fatigue resistance under actual operating conditions. The standard specifies determining the luminaire’s resonant frequency in three perpendicular directions (X, Y, and Z) and applying a reasonable acceleration value at a frequency slightly below that resonant frequency (within 2 Hz). The standard specifies the test duration, acceleration value, and results evaluation method, which are explained below.

Confirm the center of gravity and resonant frequency

The first step in the test is to determine the luminaire’s center of gravity and install an accelerometer or other intensity measuring device to accurately monitor the luminaire’s motion during the vibration test. Next, the vibration exciter is activated, applying 0.2g of acceleration to determine the resonant frequency. During this process, the vibration frequency is slowly increased from a low initial frequency (e.g., 2 Hz) to observe the luminaire’s amplitude. When the frequency approaches the luminaire’s natural frequency, resonance occurs, meaning the luminaire’s vibration amplitude is significantly greater than that of the vibration table. Once the luminaire’s center of gravity and resonant frequency are determined, we can proceed to the next step.

Test duration and test acceleration value

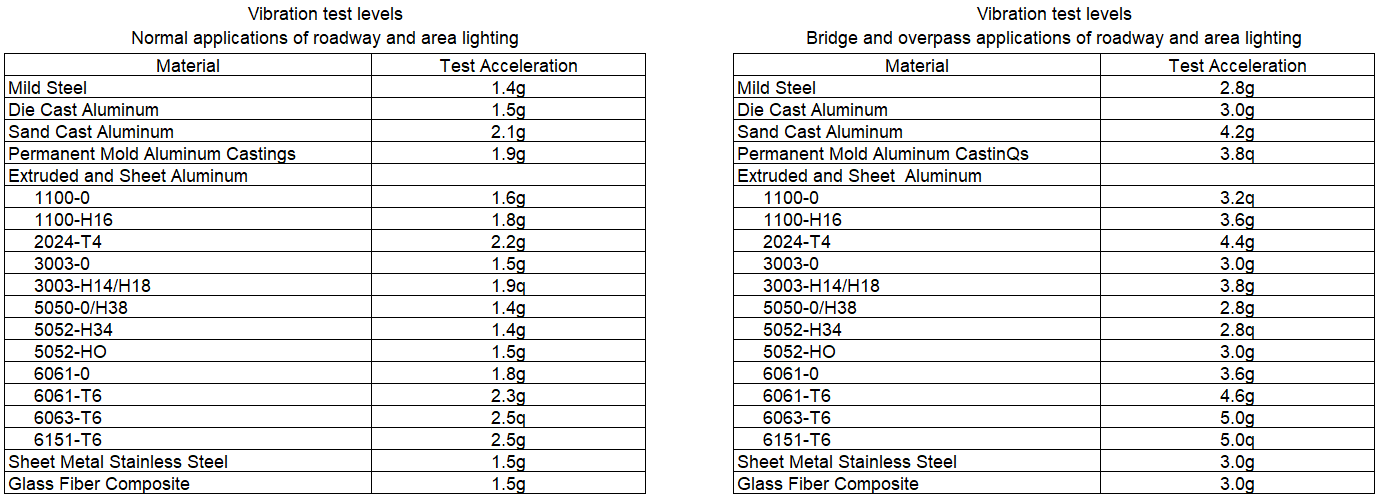

After confirming the resonant frequencies of the luminaire along the three axes (X/Y/Z) using the above method, we need to determine the test duration. The ANSI C136.31 standard specifies a test duration of T = N/60f, where N is the test frequency (100,000 cycles), and f is the test frequency. The frequency for this type of test is generally the resonant frequency minus 2. Never test at the resonant frequency, as your luminaire will quickly fail due to the unbearable acceleration. The test acceleration value depends on the luminaire’s application. For streetlights and area lights (floodlights) on ordinary roads, the standard recommends using the vibration test levels listed in left of below table. For bridge/overpass applications (such as streetlights, urban lights, and floodlights), the standard recommends using the vibration test levels listed in in right of below table. If the luminaire’s load-bearing structure is made of multiple materials, the standard recommends using different acceleration levels for each test.

Vibration test result evaluation

The core of the evaluation of vibration test results is to verify the integrity of the main structure of the luminaire under long-term vibration. Frequency and displacement need to be continuously monitored during the test, and significant changes usually indicate structural failure. If an auxiliary component (non-load-bearing part) is damaged, it can be replaced to ensure the continuation of the load-bearing component test, but the auxiliary component must be subjected to a subsequent supplementary test at a lower acceleration level. The judgment that the luminaire complies with the corresponding vibration test must meet the following requirements: the luminaire as a whole must not show any fatigue cracks or structural damage includes glasses and lens (Lens and light distributions), the casing should remain intact, and the safety-related electrical spacing (More about creepage distances and clearances) must not be reduced. The anti-loosening performance of the mounting bolts needs to be evaluated separately, and the residual torque after the test must not be less than 80% of the value specified by the manufacturer. Damage to the replaceable light source is not considered a test failure, but the integrated light source must remain in normal working condition after the test.

Vibration test of ZGSM LED lamps

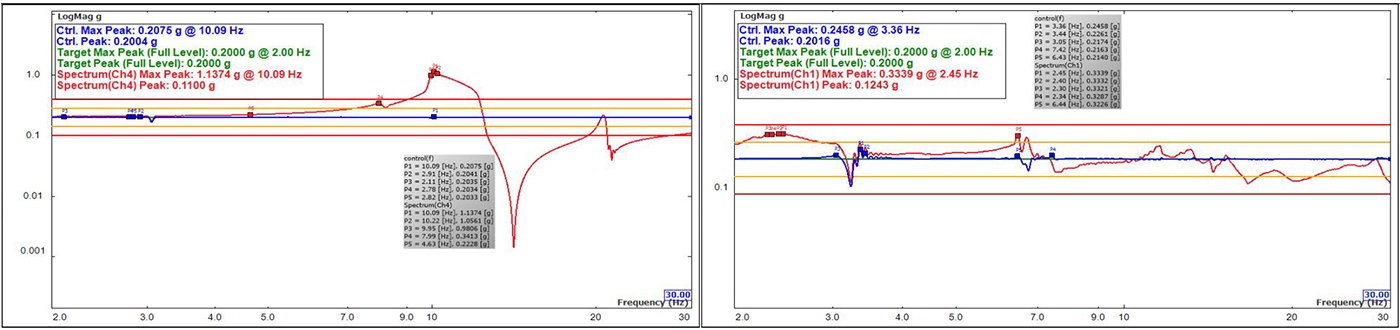

ZGSM’s luminaires undergo rigorous vibration testing, such as the 1.5G vibration test for H, the 3G vibration test for Rifle (ZGSM Rifle series), and the Kmini2. While the 1.5G vibration test generally meets the requirements of many road projects, many projects now require 3.0G or even the higher 3.8G vibration tests. ZGSM considers these requirements to be stringent. ANSI C136.31 only requires over 1.5G for streetlights on overpasses and floodlights in tunnels with die casting aluminium. For example, the 3G vibration test of Rifle with small-size confirms the resonant frequencies in all three axes (X, Y, and Z) and rigorously tests each axis (X, Y, and Z) for 100,000 cycles. In step 1 of the previous section, we can see the test curve during the vibration test, which shows the amplitude variation of the lamp at different frequencies. If no resonance occurs, the swept frequency used in the swept test is 30Hz.

The following ZGSM products, including streetlights, floodlights, and urban lights, have passed various levels of vibration testing. In addition to vibration testing, these ZGSM products have also passed numerous other certifications and reports, including structural testing reports such as IP, IK, and salt mist testing, photoelectric parameter testing reports such as LM79, LM82, IEC62722, and ISTMT, and overall lamp certifications such as ENEC, ENEC+ (What’s ENEC+ and ZGSM ENEC+ street lights), Darksky (More about Darksky?), RoHS, and UL. This comprehensive range of product certifications makes these products ideal for bidding projects. If you are interested in these products, please click on the corresponding images for more information.

Summary

Vibration test is critical for ensuring the long-term reliability of luminaires in vibrating environments such as roads, bridges, and tunnels. It effectively simulates continuous mechanical vibrations caused by traffic or wind, verifying the durability of product structural design and manufacturing processes. ANSI 136.31 and IEC 60068-2-6 are two commonly used industry standards. Vibration testing conducted according to the former is required by many projects, as it primarily serves as a specialized standard for road and area lighting fixtures. The standards explicitly require luminaires to determine resonance frequencies along the X, Y, and Z axes. Based on application scenarios (standard roads or bridges/overpasses), corresponding acceleration levels (e.g., 1.5G or 3.0G) are selected for 100,000-cycle testing. Passing certification is determined by ensuring no structural damage to the luminaire body, no loosening of critical components, and no changes in electrical safety clearances post-testing. ZGSM’s products (ZGSM product ranges) strictly adhere to these standards and have successfully passed vibration tests (primarily at 1.5G and 3.0G) for various luminaires, making them a preferred choice for road lighting and area lighting applications. ZGSM also provides users with various other certifications to help clients win projects. Contact ZGSM for more details.

Related Products

Related Blogs

Related Cases

People also ask

Author introduction

Hello Customers,

My name is Taylor Gong, I’m the product manager of ZGSM Tech. I have been in the LED lights industry for more than 13 years. Good at lighting design, street light system configuration, and bidding technology support. Feel free to contact us. I’m happy to provide you with the best service and products.

Email: [email protected] | WhatsApp: +8615068758483