LED binning – Critical step in quality control of LED lights

LED binning – Critical step in quality control of LED lights

Introduction

Have you ever encountered a situation where, within the same batch of lighting fixtures, different sampled units exhibit significant differences in parameters such as luminous efficacy, color temperature, and wattage? While these differences objectively exist, we must control them within strict limits; otherwise, the product is considered substandard. For example, if the color temperature of UFO highbay lamps installed in the same factory varies excessively, users will perceive these differences, leading to a poor user experience. Similarly, if the luminous efficacy and wattage of streetlights differ significantly, the total luminous flux emitted will inevitably vary considerably, resulting in uneven illumination (How to improve uneven lighting?) of the road surface and affecting driving safety. As industry professionals, we need to understand the origins of these differences, and different LED binning is a major cause. Therefore, precise LED binning is a crucial step in reducing differences originating from the light source. This article will focus on what LED binning is, its benefits, the key parameters upon which LED binning is based, and how to conduct effective testing. Let’s delve into the main text to learn more.

What’s LED binning?

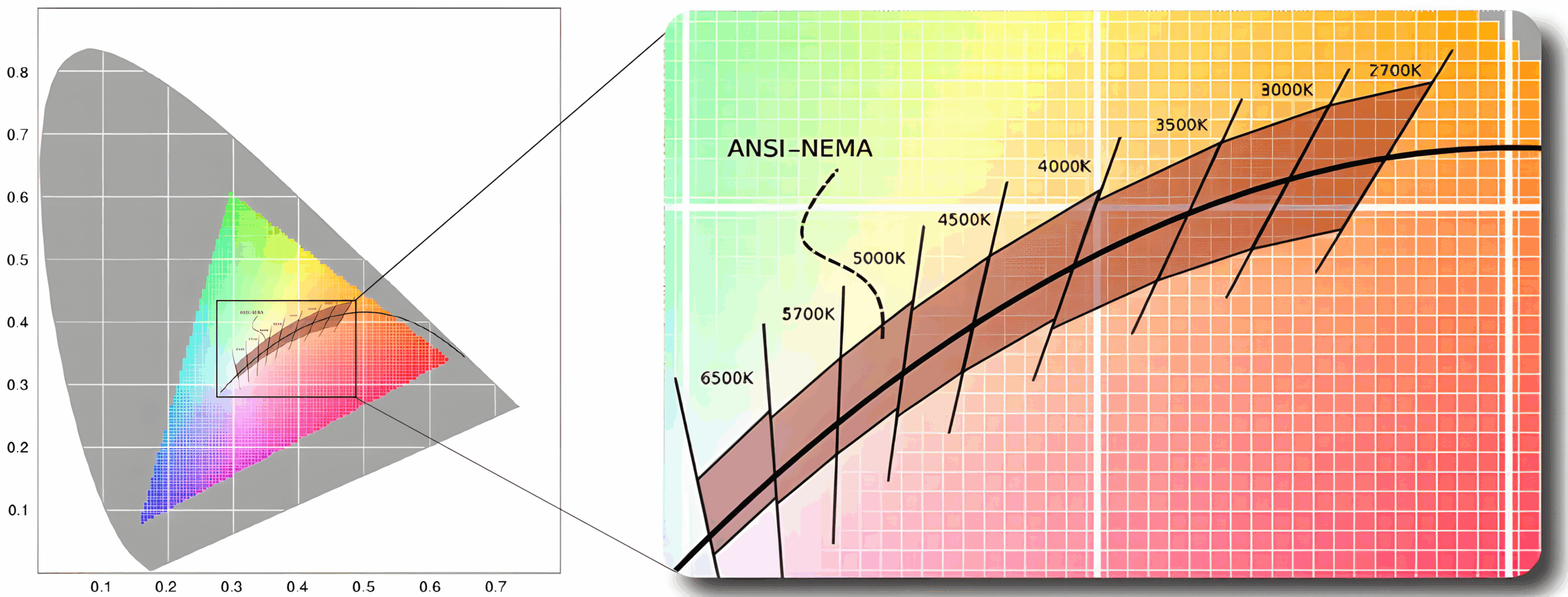

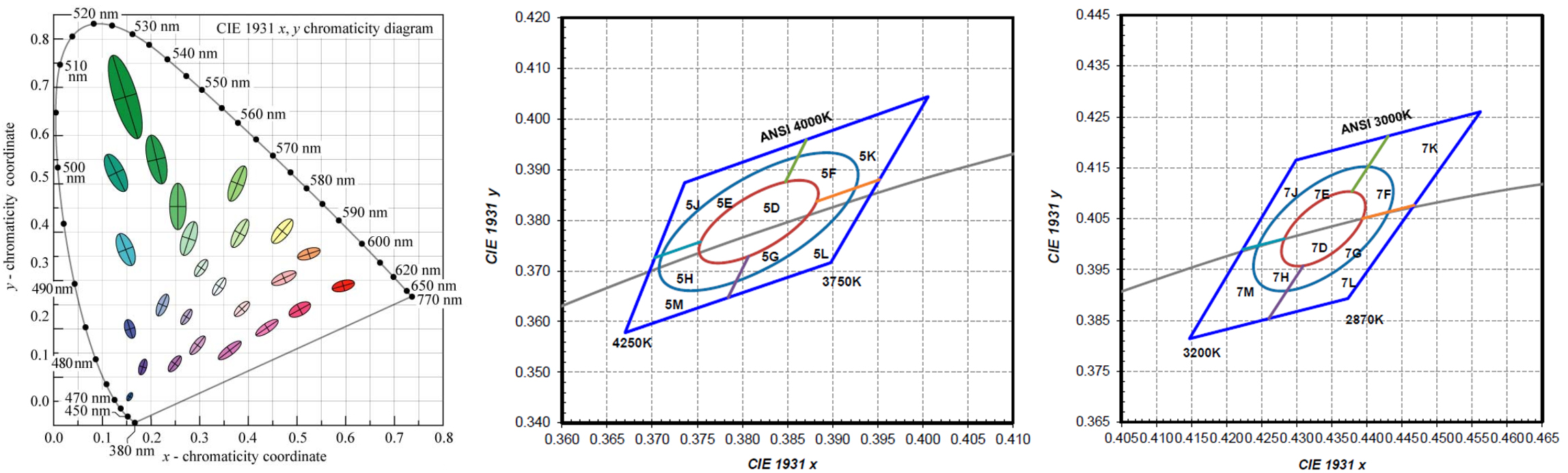

LED binning is a method for managing and classifying LED chips based on key parameters such as color temperature, luminous flux, and forward voltage. This method involves precisely measuring LEDs and dividing them into multiple sub-levels (bins). For example, LEDbinning of LED chips’ CCT can significantly reduce color differences between different LED chips or finished lamps, ensuring color consistency. In color binning, the industry generally refers to the ANSI C78.377 standard for detecting and screening the color coordinates of LEDs. This standard is based on the MacAdam ellipse theory, and common requirements include controlling color differences within 4 or 7 steps to ensure that color differences between LED chips are imperceptible to the human eye. Of course, in addition to industry standards, individual LED manufacturers can also develop their own internal binning standards based on their product specifications. Besides color binning, LED binning also involves luminous flux, voltage, and CRI (CRI vs luminous efficacy), which will be discussed in detail in the next section.

Key parameters for LED binning

In addition to die bonding, wire bonding, and encapsulation, LED manufacturing involves a crucial step: LED binning. Binning is primarily based on photoelectric parameters, with common binning standards including color coordinate tolerance (e.g., ±0.003), luminous flux binning (e.g., ±5%), and forward voltage binning (e.g., ±0.1V). After binning, LEDs are categorized and packaged according to their color zone, luminous flux, and voltage codes to ensure high consistency within the same batch. For example, Lumileds’ LED specifications primarily categorize LEDs by luminous flux, CCT, voltage, color tolerance, and color rendering index.

Luminous flux binning: Luminous flux is a key indicator for LED users. Grading ensures the uniformity and consistency of brightness in LED products, meeting specific brightness requirements.

Correlated color temperature binning: For white LEDs (Tunable white lighting solution), color temperature is a crucial parameter, determining whether the LED’s hue is warm, cool, or pure white. Correlated color temperature binning allows LED products to be categorized according to color temperature ranges to meet the needs of different application scenarios.

Chromaticity coordinate (x, y) binning: Chromaticity coordinates (x, y) define the LED’s specific position on the chromaticity diagram and are a quantitative indicator of color. Binning of chromaticity coordinates ensures the accuracy and consistency of LED product colors from the source.

Color rendering index (CRI) binning: The color rendering index (CRI) is directly related to the degree of color change of an object illuminated by light. For LED lighting products, the CRI is a very important parameter. CRI binning ensures the LED product’s ability to reproduce object colors in different application scenarios.

What’s the benefits of LED binning?

Core step of LEDs production

White light-emitting diodes (LEDs) produce white light by first emitting light from a blue LED, then directing that energy onto a yellow phosphor to create other colors of light, which are then mixed to form white light (How to get white LEDs?). It’s easy to see that variations in the blue LED and the phosphor affect the emitted white light. For example, if the blue light is slightly closer to ultraviolet or cyan, the LED will emit different colors. Slight differences in the phosphor’s mixing ratio or thickness will also affect the emitted light. Therefore, LED chip sorting is essential. In this way, LED chips are meticulously categorized using highly advanced computers that rapidly perform photometric and electronic measurements. Otherwise, LEDs from different manufacturers or even different batches from the same manufacturer would exhibit differences, which would obviously hinder manufacturers from selling their products, as downstream companies would be unsure whether they had selected the right product.

Color and efficiency tolerance control

CCT, color tolerance, and luminous efficacy are key parameters that LED lighting manufacturers focus on. Luminous efficacy is relatively easy to understand; selecting LEDs with the same LED binning ensures that the cost-effectiveness of the luminous efficacy is within the design range, avoiding situations where some lamps have low luminous efficacy while others have exceptionally high luminous efficacy (What’s luminous efficacy?). CCT and color tolerance need to be considered together. Many buyers need to confirm the color temperature when selecting products; we simply need to choose a suitable color temperature, and the seller will provide products with the corresponding parameters. Color tolerance is a more granular parameter, because even among 3000K LEDs, their colors (i.e., color coordinates) can have slight differences. LED binning ensures that the color temperature (color coordinates) is strictly controlled within the allowable deviation range, thus preventing these color differences from being perceptible to the human eye.

Voltage matching for reliability

LEDs are current-driven devices, and their brightness is primarily determined by the amount of current flowing through them. For example, in H and Hevo streetlights (parallel circuits), current automatically flows to the module with the lowest impedance (represented by the lowest forward voltage). Without voltage drop sorting, the chip(s) with the lowest forward voltage in the module will bear excessive current (the greater the difference, the greater the current difference), resulting in higher temperatures and accelerated light decay (What’s light decay?). In severe cases, it can even cause the LED chips to burn out due to overload.

How LED binning works?

Traditionally, light-emitting diodes (LEDs) are tested and binned at a pad or junction temperature set to 25°C. However, LED luminaires operate at much higher temperatures in real-world applications (LED junction temperature- more about working temperature of LEDs and LED driver). If tested at 25°C, the actual performance of an LED in a real-world application often differs from the nominal performance advertised in the datasheet. So, how can the impact of temperature on performance be reduced? Lumileds has been conducting LED binning at high temperatures for several years. For example, their LUXEON 3030 2D series undergoes hot-targeted color temperature testing at Ta=85°C to determine if the LED’s color temperature falls within the target range. Binning at a typical application temperature of 85°C (high-temperature color temperature targeting) ensures no color shift after installation. Furthermore, their epoxy molding compound (EMC) encapsulation process makes the Luxeon 3030 2D more reliable in harsh environments. Of course, besides CCT, Lumileds also performs LED binning for voltage, luminous flux, and CRI at 25°C.

Taking CCT (color coordinates) as an example, the most widely used method in LED classification is the MacAdam ellipse method. Proposed by MacAdam in the 1940s, this method is based on a key discovery: the human eye’s ability to distinguish different colors is not uniform. The MacAdam ellipse divides the color space into a series of elliptical regions, each representing a range of colors that the human eye cannot distinguish. The larger the ellipse, the lower the sensitivity of the human eye to changes in that color region, and the greater the allowable color deviation; conversely, the smaller the ellipse, the more sensitive the human eye, and the smaller the allowable deviation. For white light illumination, the MacAdam ellipse describes the color tolerance range around any given color temperature point. For example, 3-step, 5-step, and 7-step ellipses define different color tolerance ranges. For instance, if the project requirement is within 5 steps, we need to select LED chips whose color coordinates lie within this ellipse after LED binning. The following are the steps of MacAdam ellipse binning.

The chromaticity coordinates of an LED are measured; these coordinates describe the color of light and are typically represented on a two-dimensional chart known as the CIE chromaticity diagram. The McAdam ellipse region in which the LED lies is determined, and the LED is assigned to the appropriate bin based on the size of the McAdam ellipse. LEDs within smaller ellipses are considered higher quality (smaller color tolerance), while those that do not meet the requirements are placed in lower quality (color tolerance) bins until they are all discarded. Luminous flux, CRI, and voltage (Output voltage and current of LED driver) can also be binned using a similar method, but instead of being based on McAdam ellipses, various standards are used.

ZGSM quality control and testing of LED lights

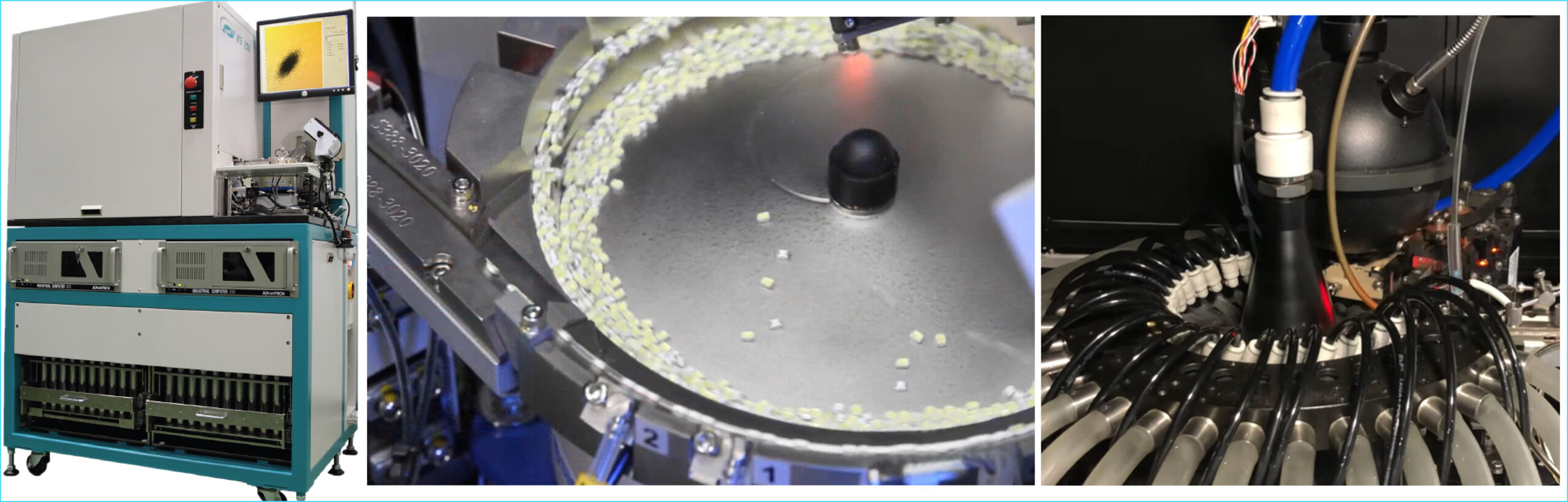

Testing of LED chips

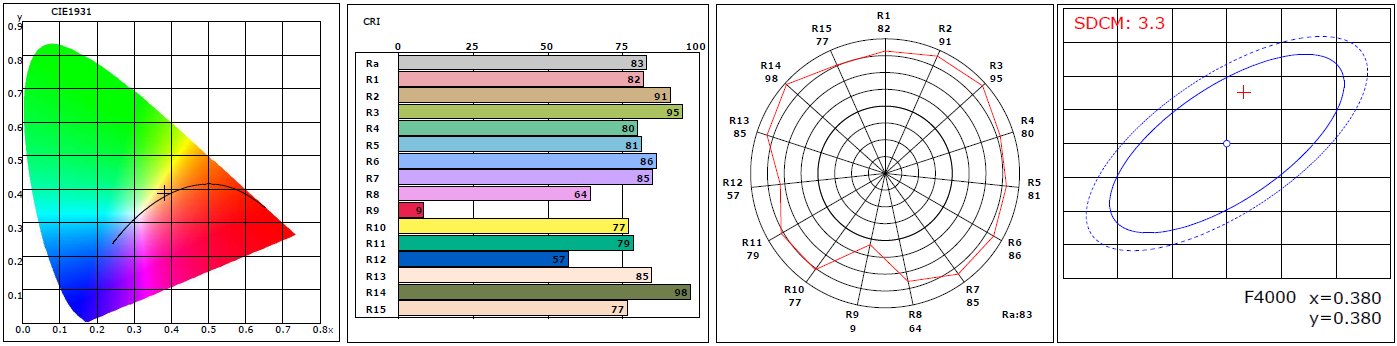

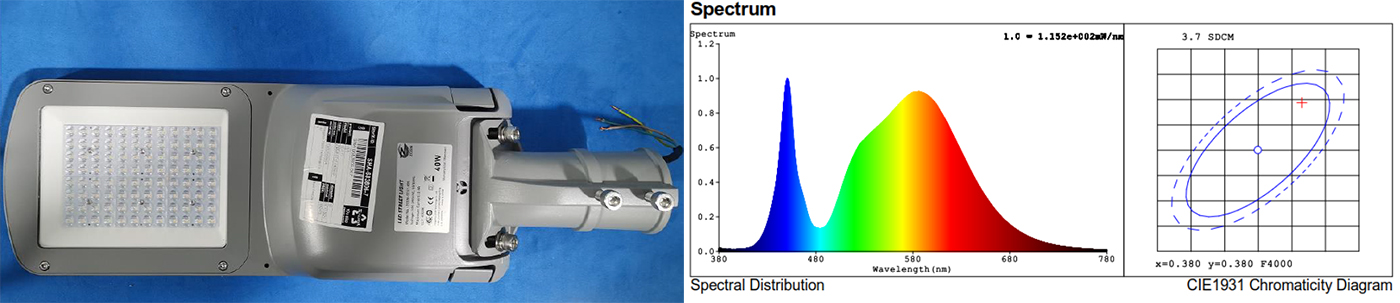

To produce qualified LED lighting fixtures, rigorous screening of LED light sources is essential. First, we need to select LED chips that meet customer requirements. For example, if a customer specifies a color temperature of 4000K within 5 steps, a color rendering index (CRI) of no less than 80, and a voltage of 5.9V (±0.1V), we can procure the corresponding LED chips. After the chips arrive, we need to inspect and test the products. Testing of the light source is primarily conducted using an integrating sphere. Integrating sphere testing is a standardized method that uses a device called an “integrating sphere” under laboratory conditions to accurately and comprehensively measure key optical parameters of LED light sources or lighting fixtures, such as total luminous flux, luminous efficacy, color temperature, and CRI. Integrators are categorized into small and large integrators based on size; here, we mainly refer to small integrating spheres. Furthermore, voltage parameter testing is also indispensable. For example, in the production of the H series street light (Click below photos to more details of ZGSM LED products), we need to screen the assembled LED modules to confirm that the voltage deviation is within the operating range to avoid the lighting fixture experiencing rapid light decay or even malfunction due to overload.

Sampling inspection

After the lamps are assembled, we conduct random checks to ensure that the photoelectric parameters of the finished LED product (ZGSM LED products) meet specifications. Unlike the small integrating sphere used for testing individual LEDs, a large integrating sphere is used for testing the whole lamp. When the LED under test is lit inside the sphere, the light it emits illuminates the inner wall of the sphere. The highly reflective diffuse coating on the inner wall causes the light to be reflected and scattered countless times. After multiple reflections, a uniformly distributed illumination field is formed on the entire inner wall of the sphere. By detecting the light intensity using a spectroradiometer mounted on the sphere wall and analyzing the spectrum of this light, we can calculate all the color parameters. In this process, we don’t need to worry about the shape of the lamp affecting the test data because the large integrating sphere uses “self-absorption calibration” or “auxiliary lamp calibration” to eliminate interference. Through random checks, we can verify whether the brightness (luminous flux) and color (color temperature, color rendering index) of LEDs produced in different batches meet specifications.

Third-party testing

When necessary, we can also conduct third-party testing on the while lamp. Common standards include LM79, EN13032-4, and ENEC+ (IEC62717). For example, LM79 provides data on luminous efficacy, CRI, and CCT. However, regarding color tolerance, it only provides results for either inside 7 Quad 4000K or outside 7 Quad 4000K, without specifying a numerical value. In contrast, EN13032-4 and ENEC+ (ZGSM ENEC+ certificated products) provide precise color tolerance values, which are crucial for projects with high color consistency requirements, but their testing costs are also higher. It is important to note that third-party testing can only be used for sampling inspection. If you are testing mass-produced goods, you must ensure randomness when submitting samples; otherwise, the test results may not represent that the entire batch of goods meets the corresponding specifications. Below are the color tolerance results from EN13032-4 and ENEC+ tests. If your project requires these reports, please contact ZGSM for more information.

Summary

LED binning is the cornerstone of high-quality LED lighting manufacturing. Its core purpose is to address the parameter dispersion issues caused by inherent differences in the manufacturing processes of blue LED chips and phosphors. As this article reveals, without precise selection through binning, these differences directly translate into inconsistencies in the color, brightness, and electrical performance of the final luminaires, leading to a series of problems such as insufficient color and brightness visible to the naked eye, or product quality issues (rapid light decay). Taking CCT and color coordinates as examples, the LED binning process measures and classifies the color coordinates of LEDs based on the ANSI C78.377 standard and the McAdam ellipse theory. Of course, we can also use similar methods to classify key parameters such as luminous flux, forward voltage, and CRI. The benefits of this process include achieving color and luminous efficacy consistency, as well as improving the electrical reliability of the system (binning of voltage). The value of binning permeates the entire quality chain. From the initial testing of LED chips (More about LED chips) by integrating sphere to the sampling inspection of finished luminaires, and then to authoritative third-party certifications such as LM-79 and ENEC+, all subsequent quality control stages verify and reinforce the results of binning. Therefore, adopting and implementing a strict LED binning strategy is a key decision for manufacturers to control quality from the source and produce high-performance and durable lighting products.

Related Products

Related Blogs

Related Cases

People also ask

Author introduction

Hello Customers,

My name is Taylor Gong, I’m the product manager of ZGSM Tech. I have been in the LED lights industry for more than 13 years. Good at lighting design, street light system configuration, and bidding technology support. Feel free to contact us. I’m happy to provide you with the best service and products.

Email: [email protected] | WhatsApp: +8615068758483