Series Primo ATEX approved LED Flood Light

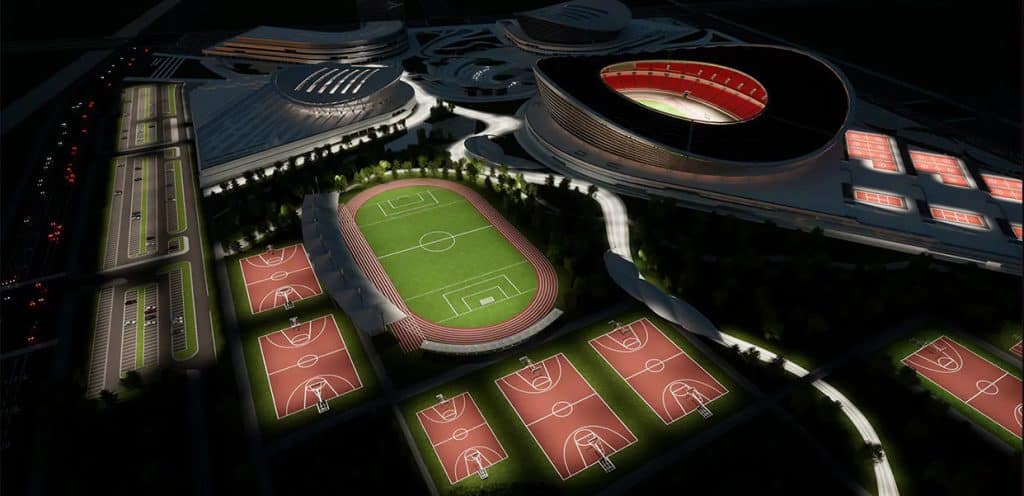

Primo ATEX LED flood light is an extension product of Primo LED canopy Light, The LED flood light fixture is equipped with LUMILEDS LEDs and INVENTRONICS/MEANWELL LED drivers which lead to a long lifespan of 100,000 hours and 5 years warranty. With the ATEX explosion-proof certification, Primo flood lamps can be used in flammable and explosive areas. By replacing optional installation accessories, Primo waterproof outdoor flood lights can be installed in gas station lighting, small stadium lighting, billboard lighting, architectural lighting, and other area lighting places. The Primo ATEX flood light is certified for use even in hazardous environments and works excellently for billboard installations. (To ensure your billboard is lit efficiently and avoids glare or light spillage, refer to our billboard illumination best practices guide for practical design recommendations.)

Product Features

- Watts: 80-150w

- Luminaire efficacy: Up to 165 lm /w

- IP66&IK08/IK10

- Die-casting housing and Tempered glass

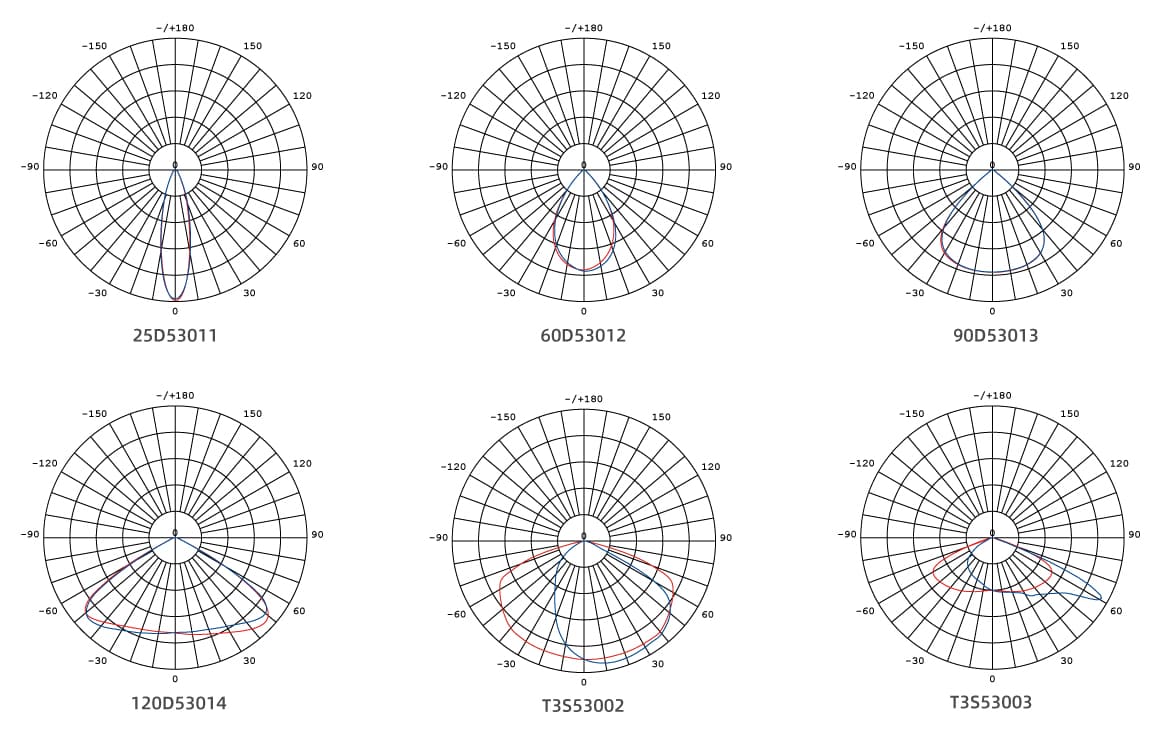

- Wide choice of optics, 25,30,60,90,120° or Asymmetry

- Tempered glass cover, easy for cleaning

- Optional installations accessories for recessed, surface, and bracket mounting

- Atex certification

| Series No | Series Primo |

| Power | 80W, 100W,120W,150W |

| Efficacy | 155-165lm/W |

| Input Voltage | 100-240/277 VAC, 50 / 60 Hz |

| Power Factor | >0.95 |

| Surge Protection | 10KV (Build-in Driver) /Extra 10KV SPD (Available on request) |

| IP Rating | IP66 |

| IK Rating | IK08 / IK10 |

| CCT | 3000K, 4000K, 5000K, 5700K |

| CRI | Ra>70 (Default) / Ra>80 |

| Operating Temperature | -40°C to + 50°C |

| Beam Angle | 25°, 60°, 90°, 120° or Asymmetrical |

| Mounting Option | Recessed, surface and bracket mounted |

| Warranty | 5 Years |

| Certification | ENEC, CE, CB, ROHS, LM79, IP66, IK08/IK10, LM80, TM-21, ISTMT, IEC62471/62788, IEC61643-11, ISO9227 |

| Control | Photocell, DALI Dimmable, Motion Sensor, Non-Dimmable, 1-10V Dimmable |

Related Products

Series ZOOM Tool-less Led Flood Light

Series HB modular design Outdoor Flood Lights

Series Stellar Driverless Led Floodlight

Related Blogs

LED Sports Lighting as per EN12193 Standard

Find solutions for your basketball court lighting

Guide for LED football pitch lighting – Stadium lights

Floodlight or spotlight?

Find a solution for your sports field – Tennis court lighting

How to Calculate Lighting Uniformity?

Guide to get billboard illuminated correctly

Guide to LED Baseball Field Lighting

Best LED Flood Light Manufacturer & Factory & Supplier in China

ZGSM as the best commercial, industrial outdoor LED flood light manufacturer, factory, supplier, and exporter in China since 2005, The factory is ISO9001, ISO14001, ISO45001, and ISO50001 certified. We have rich experience in manufacturing flood lamps with the following advantages and services:

Why Choose us as your LED Floodlight Supplier in China?

OEM/ODM/SKD

Available to do OEM/ODM/SKD for all floodlight. No MOQ limits for led flood light retailers, wholesalers, and engineering companies.

FAST DELIVERY TIME

As a reliable flood light supplier, we have stocks of raw materials for floodlights, regular delivery time is 3 days for samples and 2 weeks for bulk.

BEST QUALITY&PRICE

We use top stable quality led driver and chips like Philips driver and chips for all flood lights. Providing 5/7 Years warranty at the cheapest price.

CERTIFICATES

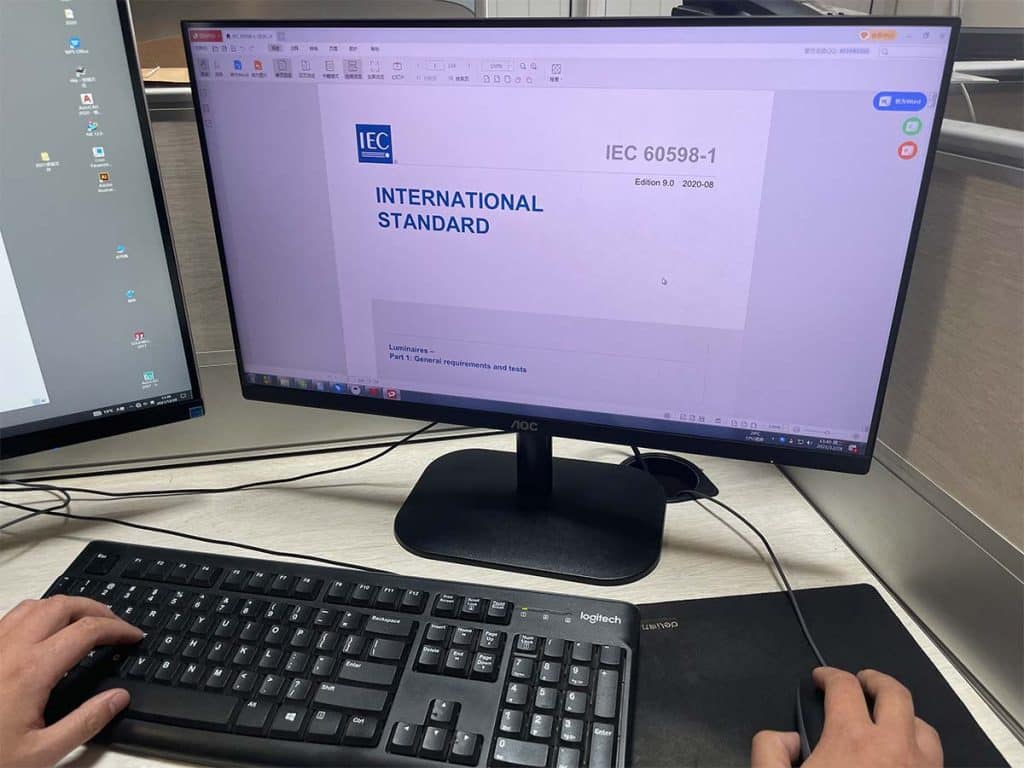

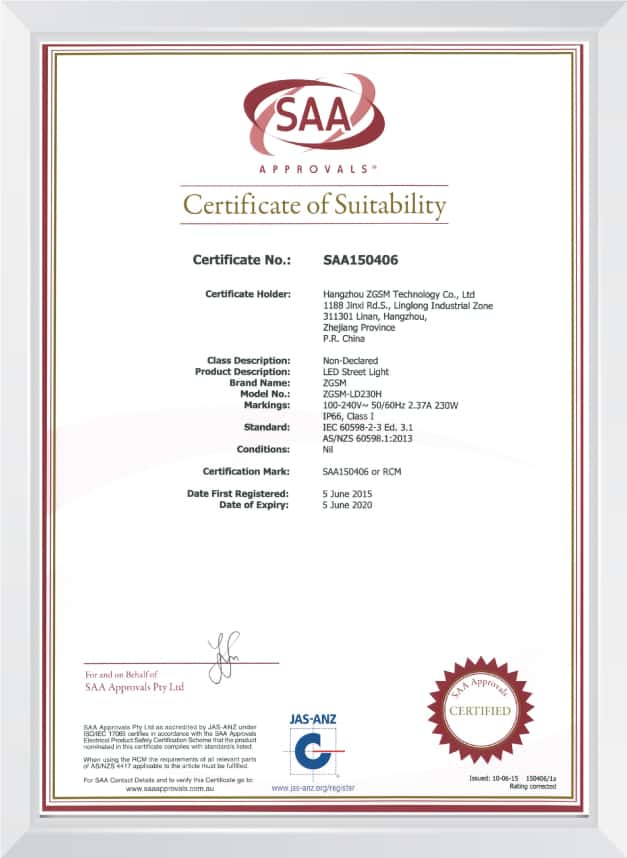

Our led flood lamps are ENEC, CB, CE, RoHS, IECEE, and SAA approved, and our factory ISO9001, ISO14001, ISO45001, and ISO50001 certified.

Certification Show

As the top manufacturer of LED flood lights in China, our LED flood lamps have complete certification and test reporting, such as ENEC, CE, CB, IECEE, SAA, ROHS, UL, IEC62471, LM80, LM79, and so on.

ENEC by TUV

CE by TUV

CB by TUV

UL

SAA

| COMPONENT | STANDARDS | TEST REPORT | CERTIFICATIONS |

| LED | LM80 | √ | |

| LUMINAIRES | EN/IEC 60598-1 and 60598-2-5 | √ | √ |

| IEC 62471 | √ | ||

| EN/IEC 60529 | √ | ||

| EN/IEC 62262 | √ | ||

| EN/IEC 60068-2-75 | √ | ||

| EN/IEC 55015 | √ | √ | |

| EN/IEC 61000-3-2 | √ | √ | |

| EN 61547 | √ | √ | |

| EN 61000-3-3 | √ | √ | |

| LM79 | √ | ||

| ISTMT | √ | ||

| TM-21 | √ | ||

| ISO9007 /ASTM B117 | √ | ||

| LED MODULE | EN/IEC 62031 | √ | |

| LED DRIVER | IEC 62384,IEC 61347-1,IEC 61347-2-13 | √ | √ |

| SPD | EN/IEC 61643-11 | √ | √ |

| FACTORY | ISO9001,ISO14001,ISO50001,ISO45001 | √ |

Get Solutions & Quotations

Please fill out the form below. We can meet your specific needs covering LED light selection, lighting design, technical support, and after-sales service. We will contact you at the earliest convenience.

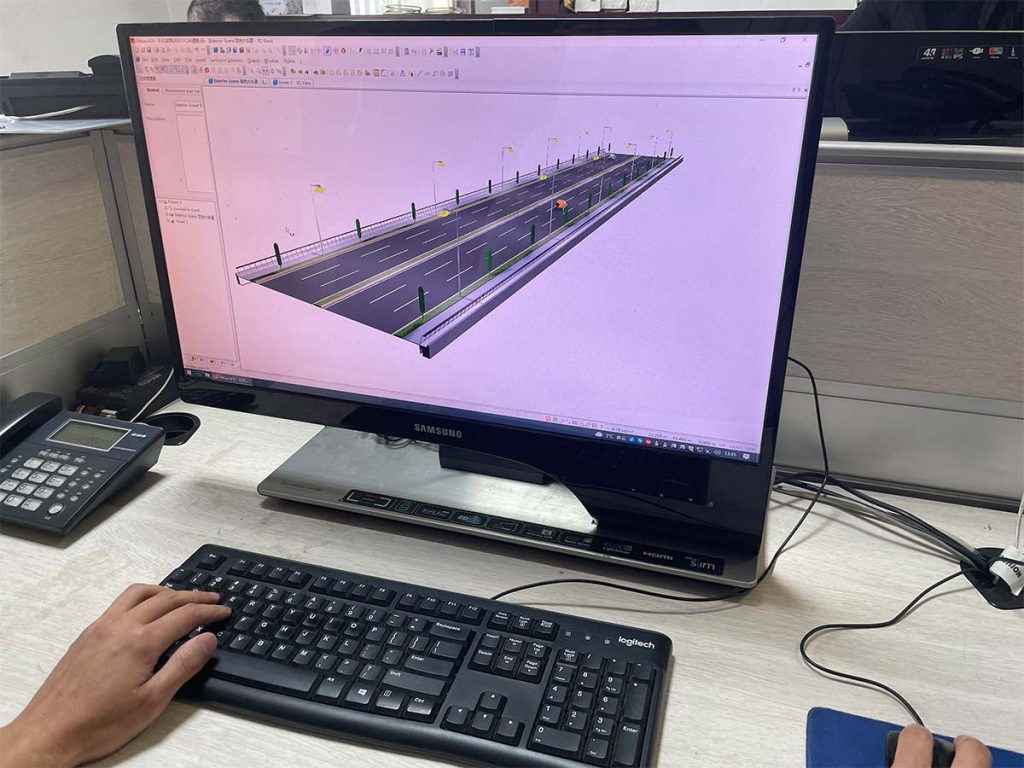

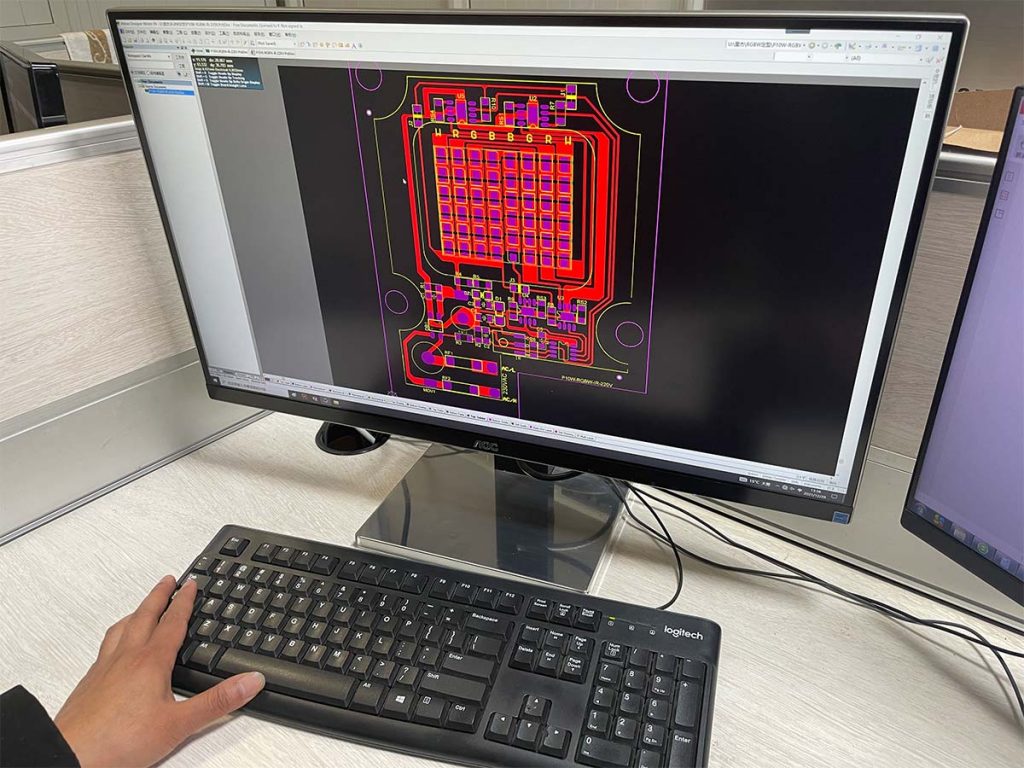

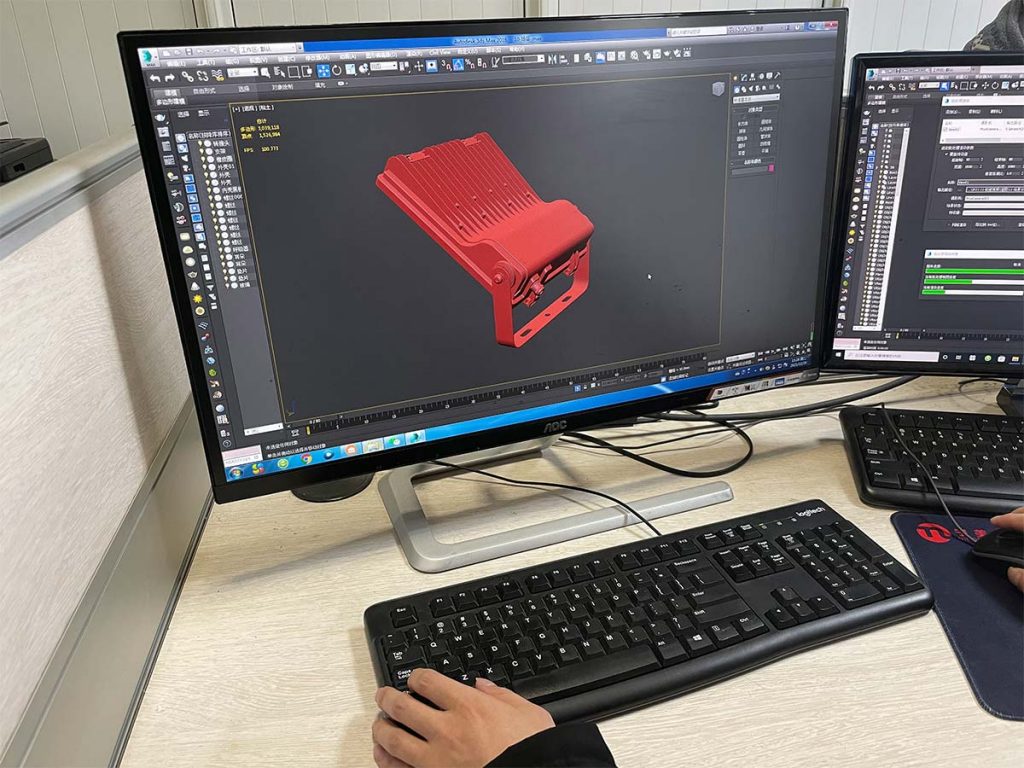

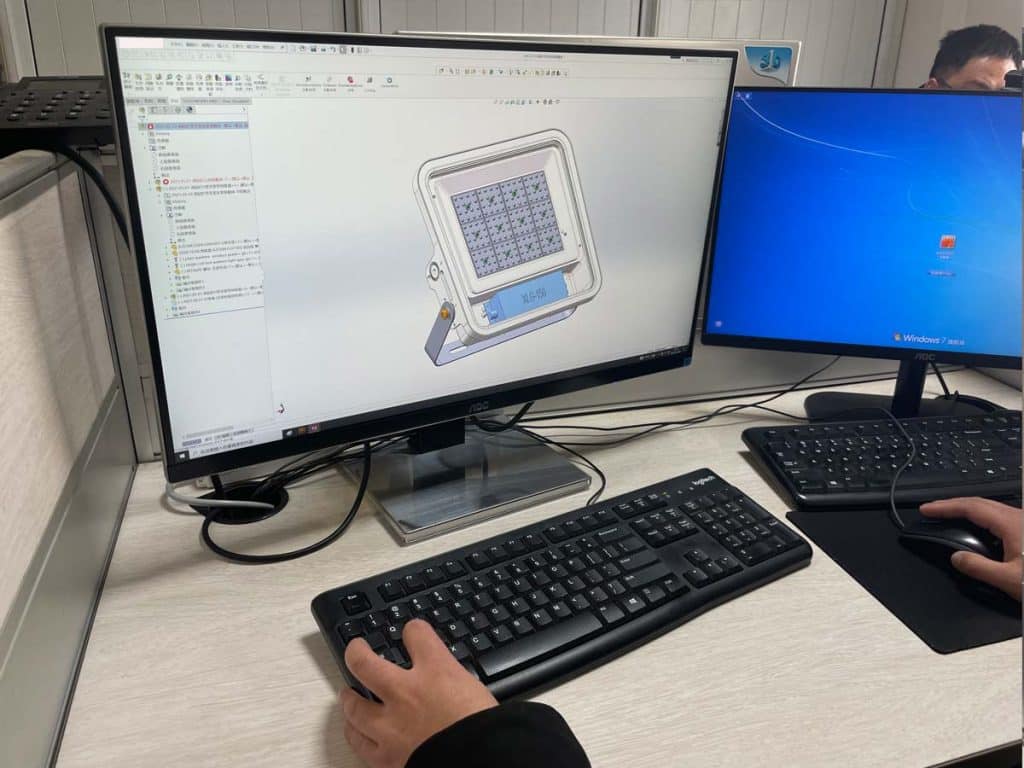

R & D Team

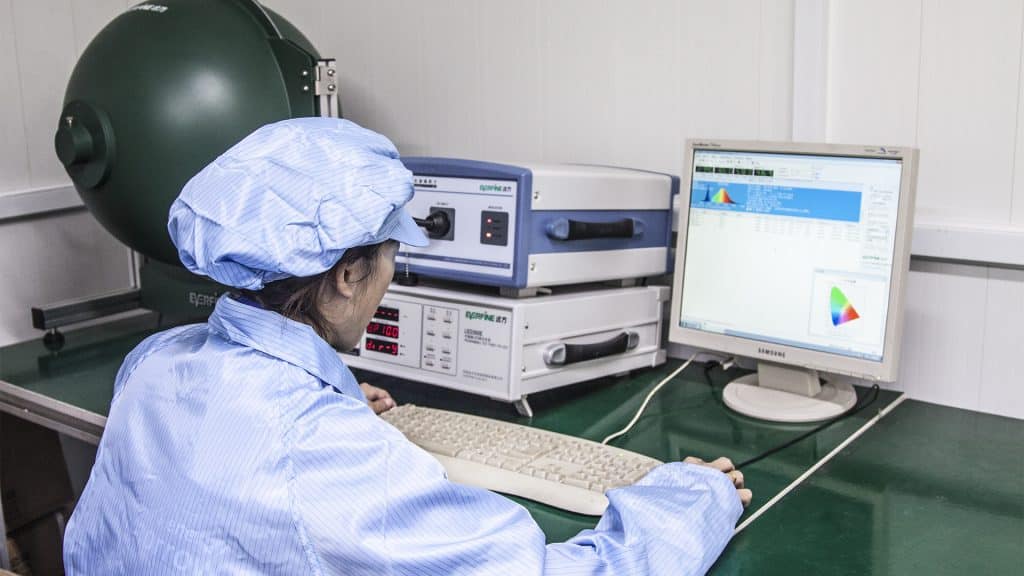

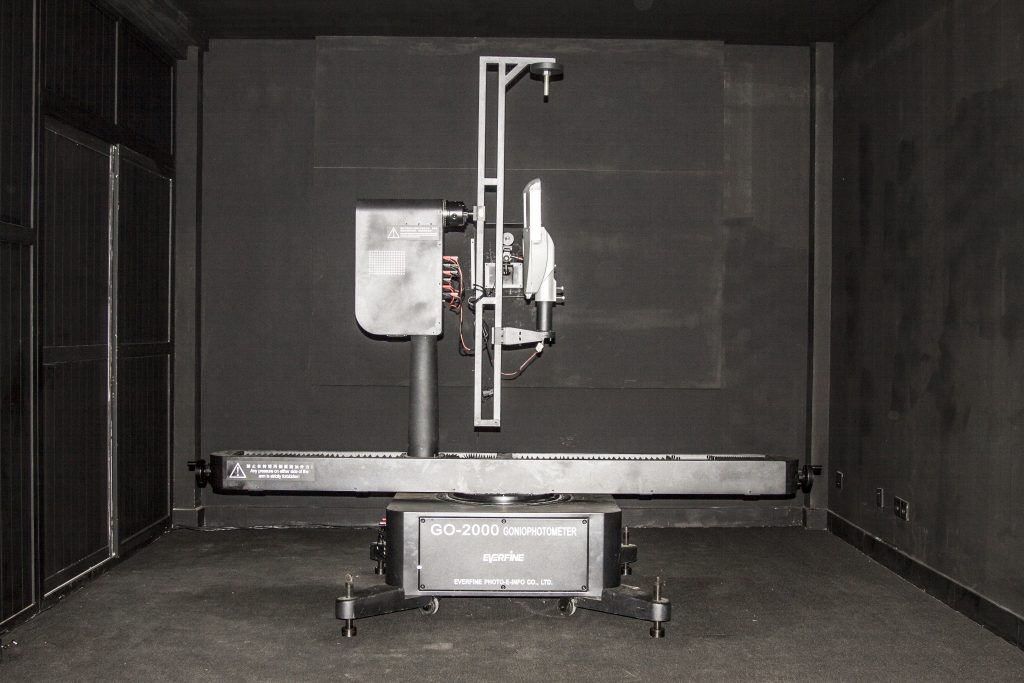

Product Testing

In order to ensure the high quality of each product, we will conduct more than 30 different aspects of testing in our own laboratory before the product goes on the market. After all the tests are passed, the product can be approved for marketing. In mass production, for some basic safety and performance tests, we will conduct 100% testing to ensure that every product delivered to the customer is perfect.